Cindy Teng, Engineer at Technical Support Division

- Customer: Objectify Technologies Pvt. Ltd

- Country: India

- Industry: Automotive

- Solution: Moldex3D Advanced Package, Flow, Pack, Cool, Warp, Designer BLM, Moldex3D Studio

Objectify Technologies Pvt. Ltd. was founded in 2013 at SIIC, IIT Kanpur with a small desktop 3D printing machine. Since then, it has become one of India’s forerunners in the field of Additive Manufacturing, 3D printing, and Rapid Prototyping in polymers as well as metal.

Summary

To reduce the cycle time and improve the quality of products, Objectify Technologies Pvt. Ltd. designed a conformal cooling channel to solve the problem. After using Moldex3D to simulate the difference between conventional and conformal cooling channel, a baffle is replaced with conformal cooling channel made by Direct Metal Laser Sintering (DMLS). The customer confirmed a reduction in cooling time and minimized warpage, validating the simulation results.

Challenges

- Reducing cooling time

- Reducing warpage within the gap and flush tolerance for part assembly

Solutions

Creating a new conformal cooling design to improve cooling efficiency. The new conformal cooling design effectively optimize the required cooling time to achieve the target temperature in a short time.

Benefits

- Cooling time reduced about 65%

- Warpage decreased around 25%

- Overall productivity enhanced approximately 50%

Case Study

With the trends of lightweight products and energy conservation, automotive industry increases the usage of plastic component to replace metal component. However, in the present study, a bending hose tube causing non-efficient cooling. Conventional manufacturing process can only create simple geometric design cooling channel which cannot cool down the part uniformly and rapidly. Poor cooling design not only reduces productivity due to high cycle time but also increases part rejection due to excessive warpage. Objectify Technologies Pvt. Ltd used Moldex3D to simulate the difference between conventional cooling channel and conformal cooling channel, realizing the advantage of conformal cooling channel by DMLS. This reduces the cycle time and deformation simultaneously.

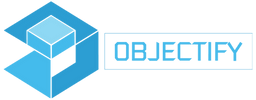

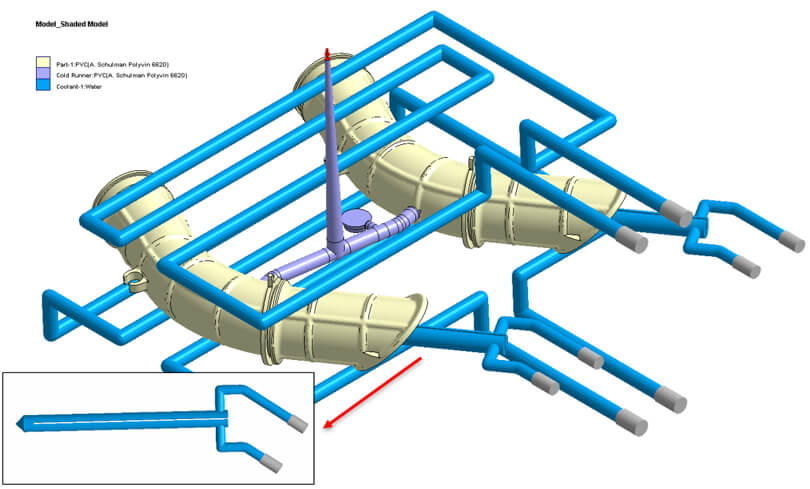

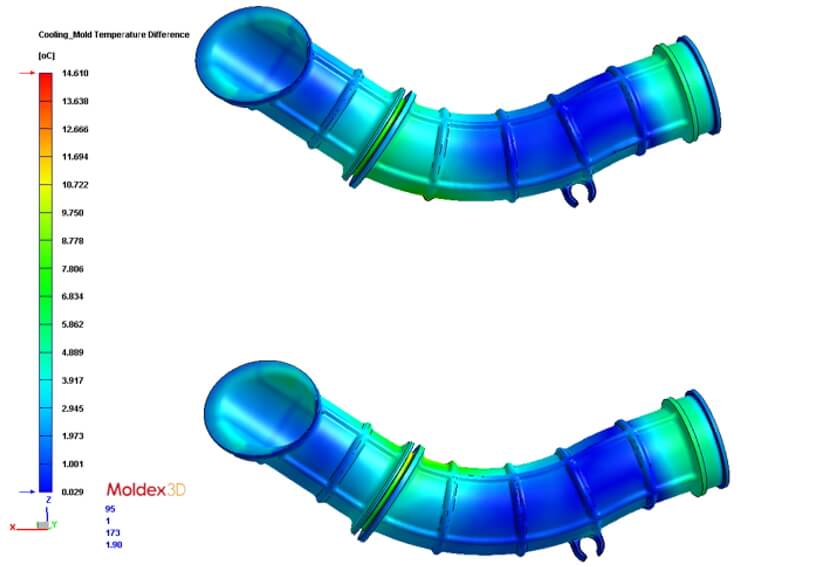

Conventional cooling channel design is shown as Fig. 1. A baffle cannot pass through the hose tube which results in non-uniform temperature distribution after cooling stage. Heat accumulates on one side of the hose tube while the other side has already cooled down and the maximum mold temperature difference is up to 70°C (Fig. 2).

Fig. 1 Conventional cooling channel design

Fig. 2 Mold temperature difference while using baffle

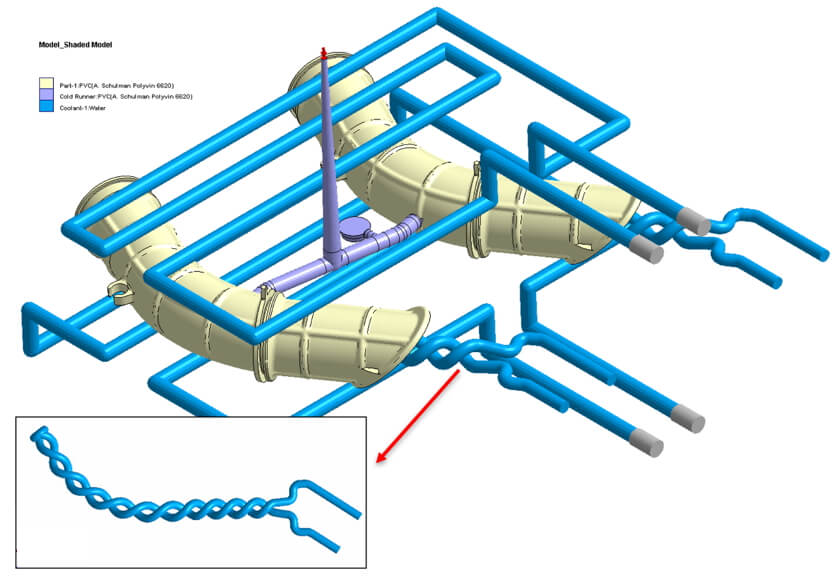

By replacing the baffle with a conformal cooling channel as shown in Fig. 3, the issue of heat accumulation is eliminated, and the mold temperature difference is reduced to 15°C. (Fig 4)

Fig. 3 Conformal cooling channel design

Fig. 4 Mold temperature difference using conformal cooling channel

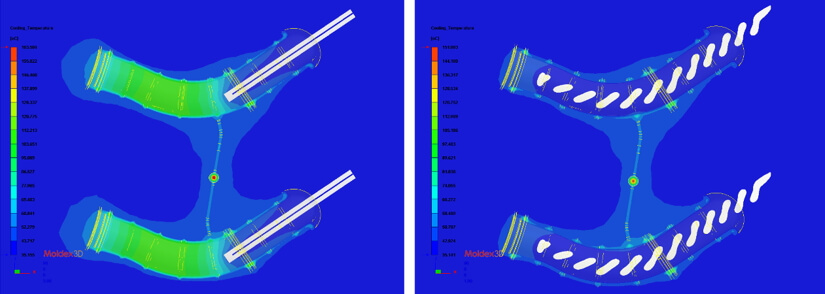

The clipping result of moldbase temperature provides a clear picture of how the cooling channel design affects the temperature distribution. In Fig. 5(a), the moldbase temperature near the baffle is low and temperature in the region inside and outside the hose tube is quite similar. On the other hand, the moldbase temperature far from the baffle is high because of the inefficient cooling. As shown in Fig. 5(b), the conformal cooling channel arranged along the hose tube results in a more uniform temperature distribution. The temperature difference between either inside and outside region or the two ends of the tube is very small.

Fig. 5 Clipping result of moldbase temperature: (a) conventional cooling channel design;

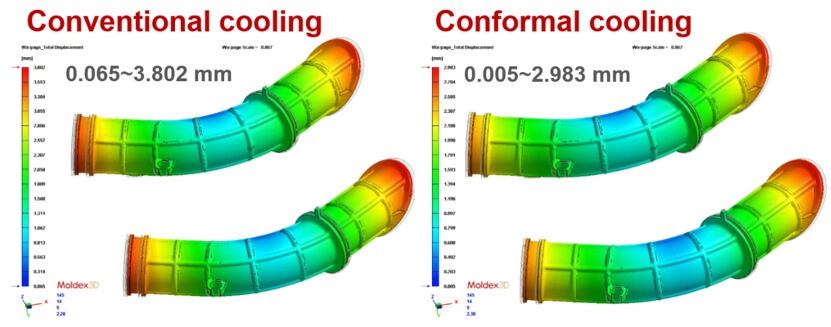

The original cooling channel design fails to cool down the product uniformly, resulting in a severe deformation issue. After resolving the heat accumulation problem with a conformal cooling channel, the deformation of the product significantly improves. The total deformation decreases from the original 3.8 millimeters to 2.9 millimeters (Fig. 6), effectively enhancing the product yield.

Fig. 6 deformation of products: (a) conventional cooling channel design; (b)conformal cooling channel design

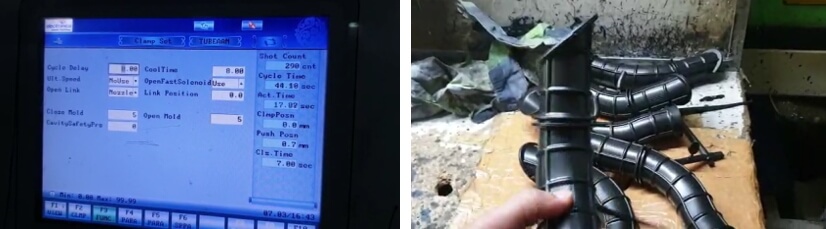

Ultimately, with the assistance of Moldex3D in modifying and predicting optimization conditions, the client successfully reduced molding time and warpage, as evidenced by on-site mold tryouts results. (Fig 7)

Fig 7. On-site mold tryouts results: (a) molding cycle; (b) optimized product.

Results

Objectify Technologies Pvt. Ltd realized the advantage of a conformal cooling channel by DMLS, confirming the accuracy of the cooling time estimation suggested by Moldex3D simulation results. The cooling time is reduced by 65% from 25 seconds to 9 seconds by transitioning from a baffle to a conformal cooling channel. Additionally, the uniform temperature distribution also decreased the warpage by approximately 25% and significantly improved overall productivity. These findings underscore Moldex3D’s exceptional performance in process optimization, offering the manufacturing industry practical and dependable solutions that drive enhanced production efficiency.