Composite Molding

Release Composite Molding Potential

Moldex3D provides various realistic 3D simulation solutions for the composite molding process, such as short & long fiber injection molding, SMC/BMC/GMT/D-LFT compression molding, various RTM (Vacuum RTM, High Pressure RTM, Wet RTM) and Hybrid molding, etc.

Our Services

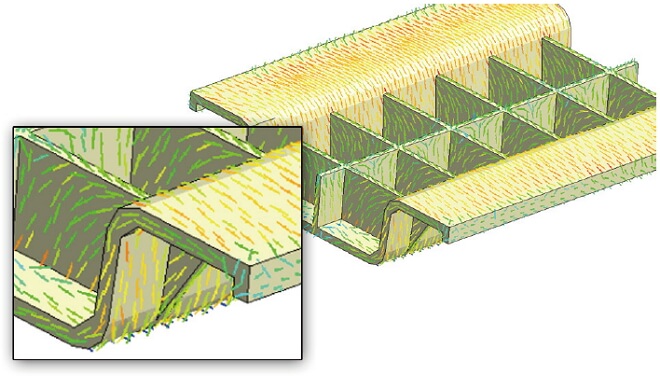

Fiber Orientation Prediction

- Visualize fiber orientation, length, and distribution inside fiber-reinforced plastics.

- Evaluate the filler effect to mechanical properties and final shrinkage

- Optimize process conditions to enhance the part strength.

- Support short, long, flat fiber and flake orientation simulation.

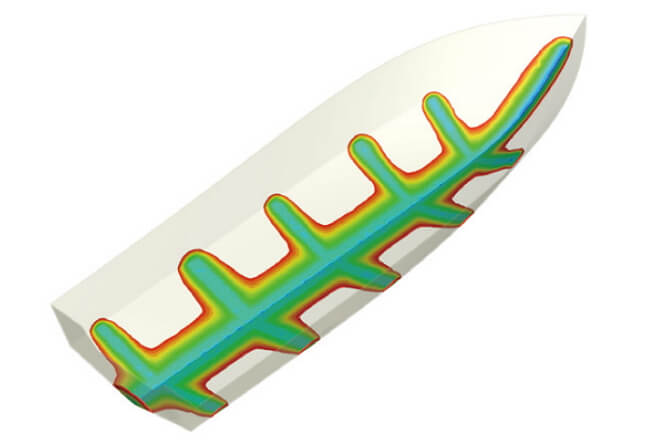

Resin Transfer Molding

- Predict resin flow behavior through anisotropic porous media.

- Decide appropriate fabric materials, and optimize process conditions.

- Control resin infusion by pressure or flow rate.

- Capture cure reaction trend during molding through viscosity and curing kinetics models.

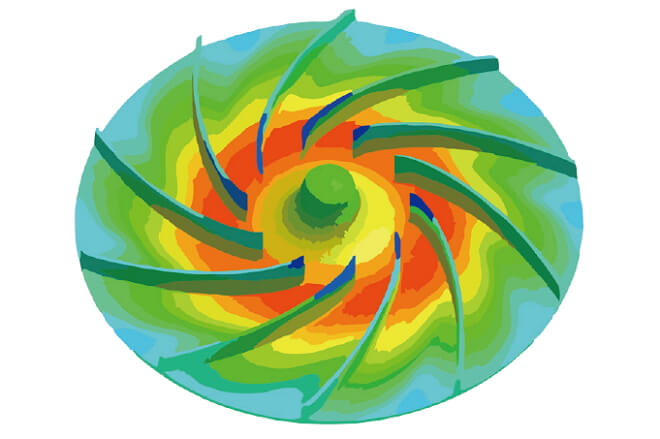

SMC/BMC/GMT/D-LFT Compression Molding

- Visualize dynamic melt flow advancement during compression molding process.

- Evaluate chopped fiber orientation prediction, compression force response and anisotropic warpage result for SMC/BMC/GMT/D-LFT compression molding.

- Predict potential molding defects, such as flashing.

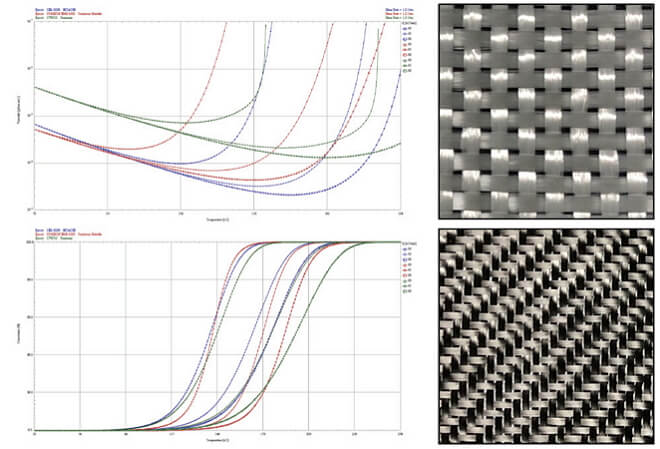

Material Characterization

- Evaluate curing kinetics under temperature variations.

- Evaluate viscoelastic properties, chemical shrinkage and thermal expansion effect.

- Evaluate the permeability and porosity of fabric layer.

FEA /Micromechanics Interface

- Export fiber orientation, anisotropic mechanical property, stress and pressure simulation results to structural analysis software.

- Validate the structural performance of products and mold sustainability.

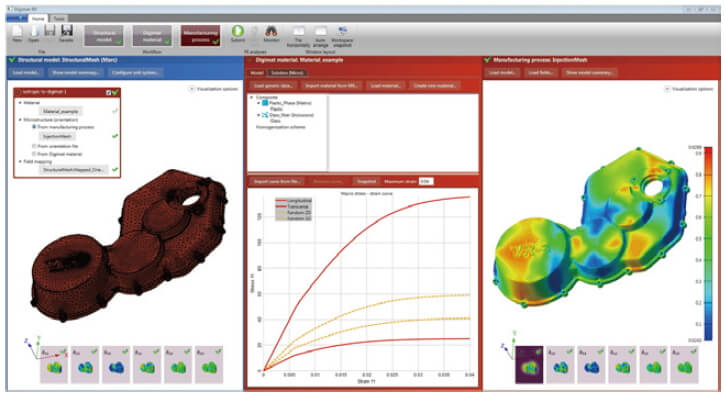

Moldex3D Digimat-RP

- Bridging manufacturing process and FEA analysis.

- Predict the mechanical behaviors of reinforced plastic with nonlinear material modeling technology.

- Define material properties and of failure criteria of reinforced plastic.

- Support automatic reverse engineering for material modeling based on experiment data.