Electronics Potting

Unleash Reliability with Electronics Potting Precision

Discover the benefits of using PU (polyurethane), silicone, or epoxy for electronic potting:

Moldex3D Can Help

Leverage Moldex3D Electronics Potting simulation to optimize electronic potting processes and enhance outcomes. Predict air trap locations, assess temperature variations, chemical reactions, and more for precise evaluation of product shape and stress distribution.

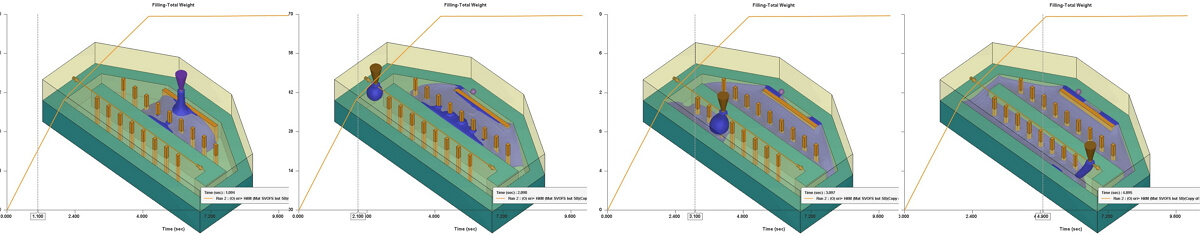

Validate and Optimize Processing Condition Settings

- Flow, temperature, phase, and conversion field simulation

- Introduce the effects of surface tension, capillary force and gravity

- Optimize the gate and runner design

- Air trap prediction

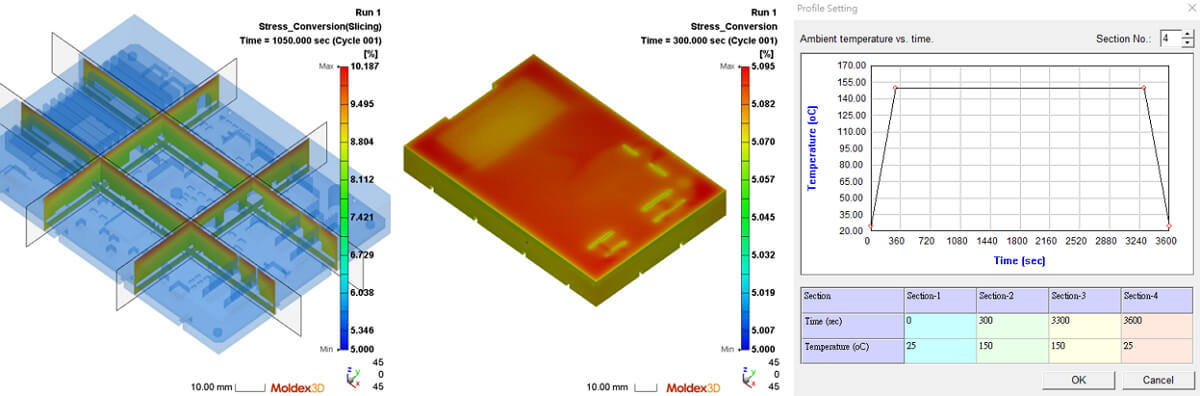

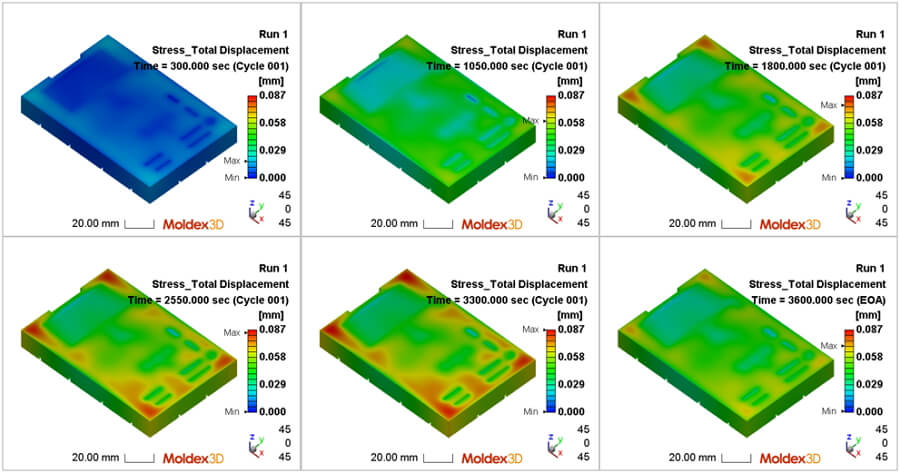

Post Mold Cure Warpage Simulation

- Observe the phase transition process through numerical simulation

- Fully consider the stress relaxation and chemical shrinkage

- Predict deformation with post-mold cure process via temperature, conversion, and stress distribution simulation

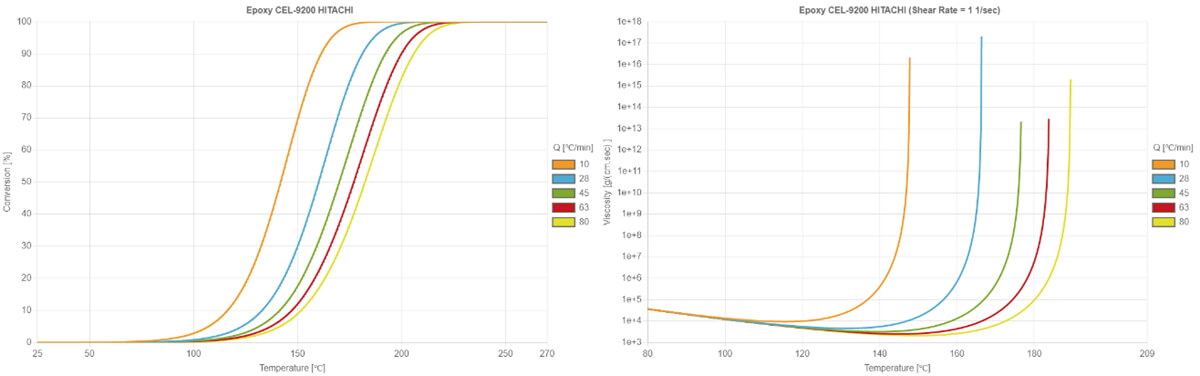

Advanced Material Property Measurement for Accurate Simulation

- Measure curing kinetics, viscosity, and viscoelastic properties for flow simulation

- Determine viscoelasticity stress relaxation, chemical shrinkage, and thermal expansion effect for warpage prediction

Electronics Potting Prevalent Application

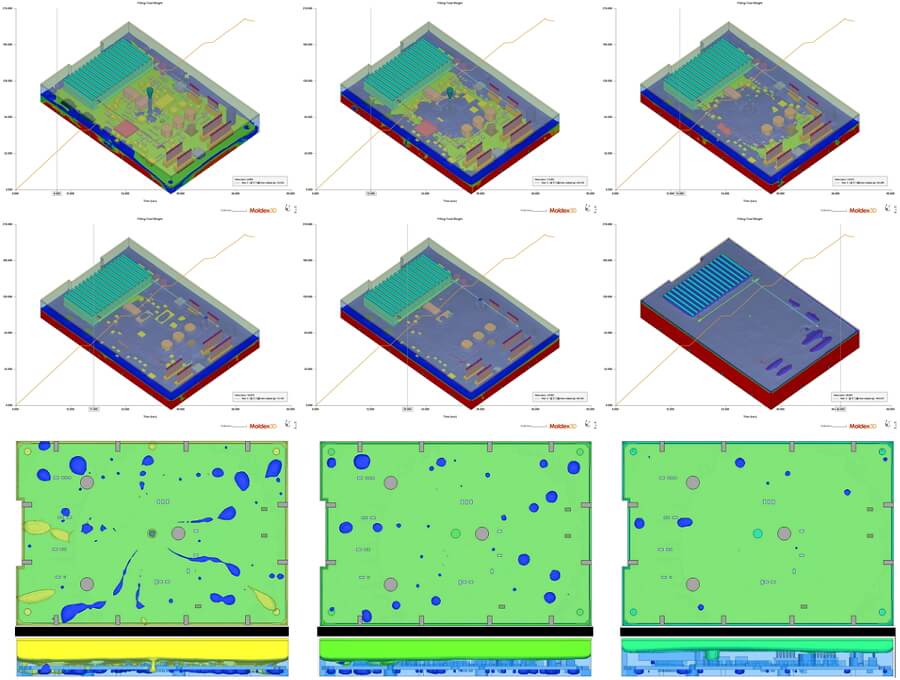

Electronics Potting for PCB Components

The most prevalent application of electronic potting is in board-level encapsulation, especially in electronic products that require PCB protection. Potting quality depends on many factors like material properties, thickness compliance, venting efficiency, and the number of bubbles.

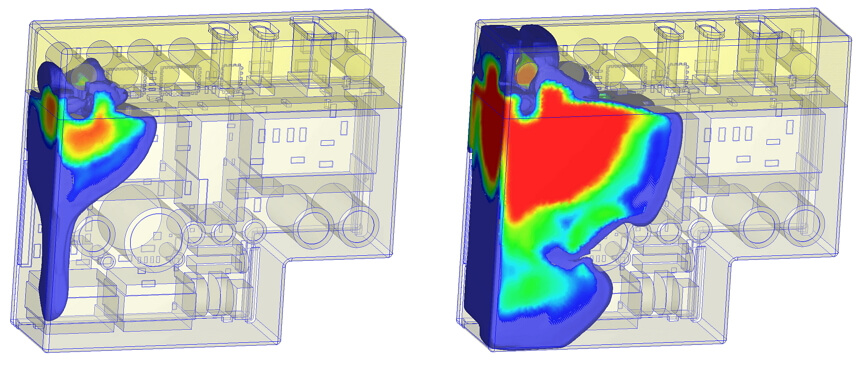

Observing air zone evolution reveals bubble movement and entrapment locations during potting. It helps user to improve the part and venting design. Additionally, the stress distribution changes over time due to the curing and viscoelastic effects. Consider those effects, Moldex3D can evaluate the final residual stress and product shape.

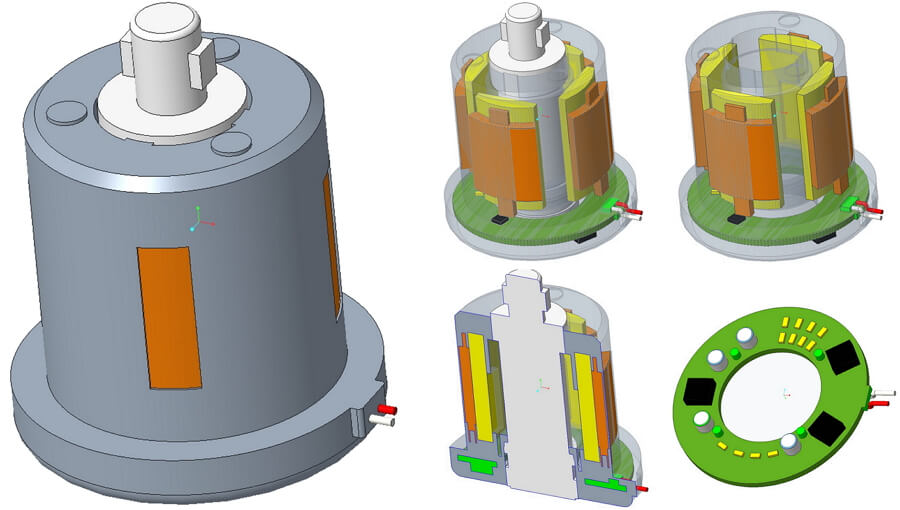

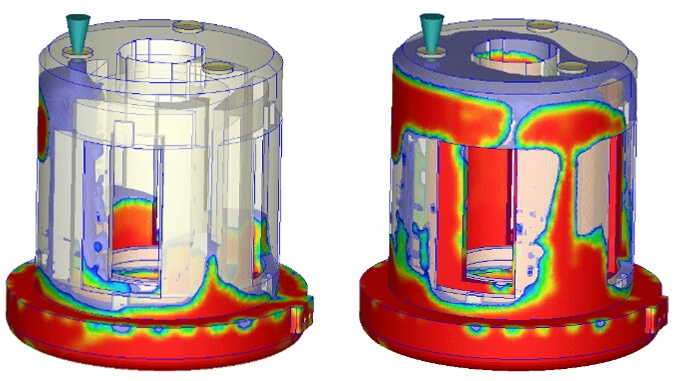

Electronic Potting for the Wound Rotor of Motors

Polyurethane (PU) or Epoxy is often widely employed in motors to protect the Wound Rotor assembly, preventing wear and tear from high-speed rotation and minimizing detachment risk due to vibrations. This extends product lifespan and can reduce size, moment of inertia, and power consumption, especially in controlling circuit boards and microcontrollers.

Moldex3D’s numerical simulation predicts bubble formation and air-trap locations during potting, aiding material selection and processing optimization. Post-mold cure analysis offers insights into curing time, chemical shrinkage, deformation from temperature variations, and stress relaxation. viscoelasticity effects.

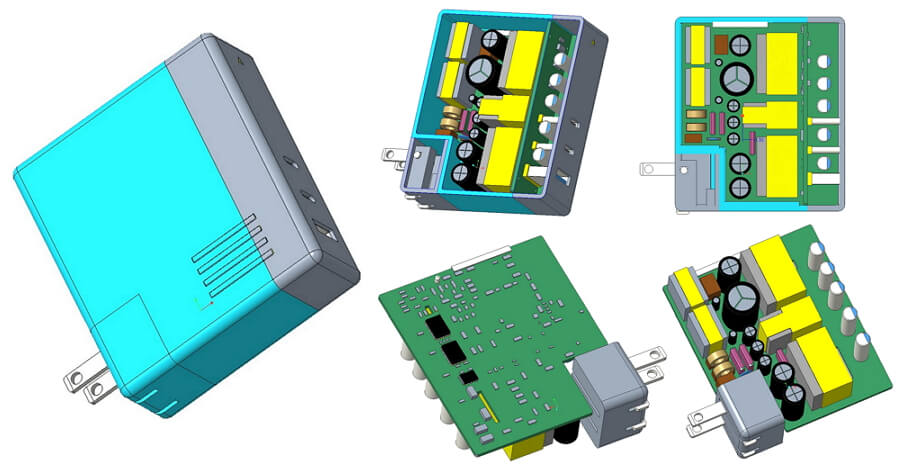

Potting Encapsulation for Mobile Electronic Products

Applying electronic potting technology to high-power gallium nitride (GaN) chargers effectively serves electrical insulation, efficient heat dissipation, and protection of electronic contacts from physical impact. This allows the product to achieve minimal size while improving reliability and product lifespan.

However, due to reduced component clearances, the design and material selection significantly impact manufacturing yield and quality. Therefore, utilizing numerical simulations to obtain optimal design parameters and material selection is crucial.