Edited by Pierre Yeh, Engineer at Technical Support Team, Moldex3D

- Customer: Free-Free Industrial Corp. (Felli)

- Region: Taiwan

- Industry: Consumer Products

- Solution: Moldex3D Advanced Package; Flow, Pack, Cool, Designer BLM

Free-Free is the leading manufacturer of acrylic storage, serving ware, tabletops, bath-ware, office products, 3C accessories, and pet products. Free-Free was established in 1985 by President Mike Liu and General Manager Sylvia Chang. Free-Free Industrial Corp is also known as “Felli” has almost 3 decades of experience in the acrylic industry. (Source: https://www.felli.com.tw/about.php)

Executive Summary

Felli engineers were tasked with producing mass quantities of a food storage container. The development objectives were to achieve shorter cycle times and higher success rates and to reduce the need for post processing. The part was gating with a valve gate hot runner system to reduce materials and avoid surface defects. However, the corner effect was induced by the valve gate hot runner system and resulted in unbalanced flow and caused weld lines, air traps, and halo marks. Felli engineers used Moldex3D to perform a series of analyses to determine the root cause of the corner effect and validate the proposed solution and were finally able to achieve consistently high-quality production.

Challenges

- Unbalanced flow

- Air traps and weld lines

- Halo marks

Solutions

Utilized Moldex3D’s Flow and Hexa-based meshing technology to find the solutions to the flow imbalance

Benefits

- Eliminated surface defects

- Improved success rates by 99%

- Consistent production

Case Study

This product is a transparent storage tank made of AS, with size 140mm * 140mm * 210mm (Fig. 1). The mold is designed as a two-cavity mold, which is filled from the bottom of the tank using a valve gate hot runner. The process was planned for mass-production and requires 24 hours of continuous production. Therefore, how to achieve stable and continuous production was the most important issue. Although a valve gate hot runner system and excellent cooling channel design had been used to improve the surface defects and successfully reduce molding cycles, there were still welding lines, air traps and heat flow marks caused by flow imbalance.

Fig.1 The Product: transparent storage tank

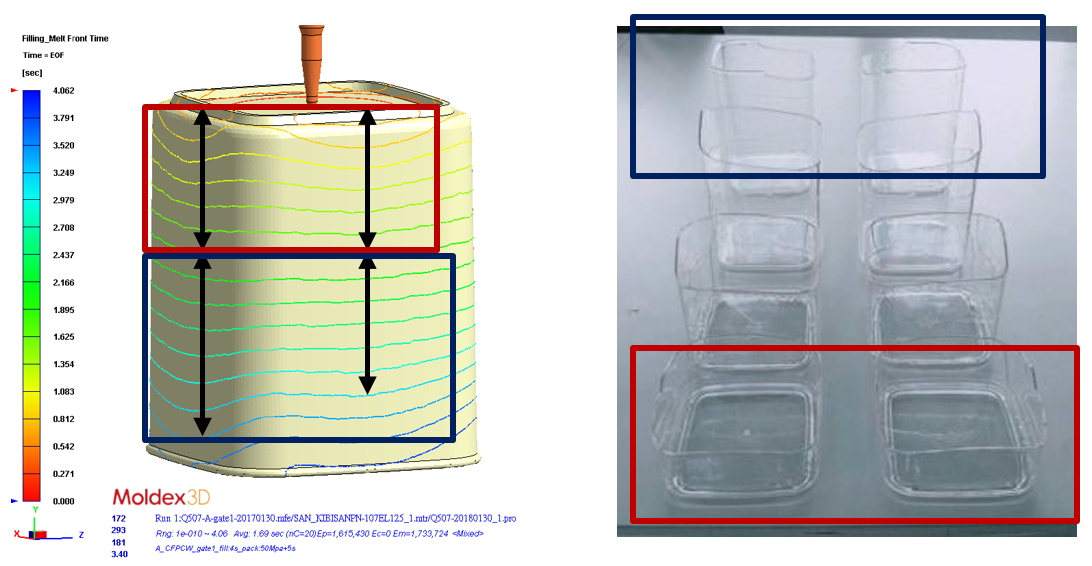

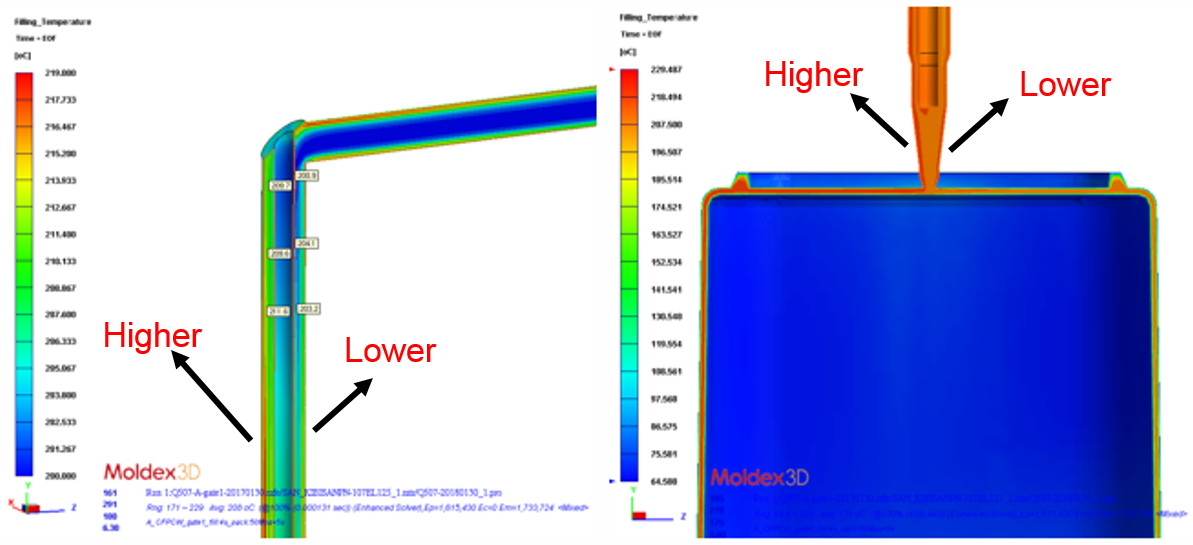

According to the Moldex3D simulation, there was indeed a phenomenon of flow imbalance (Fig. 2). Further observing the temperature result profile, it can be found that the hot melt glue spreads to the outside due to the corner effect caused by the hot melt bypassing the valve pin, and continues to the final product (Fig. 3).

Fig. 2 The flow imbalance indicated by the melt front contours in Moldex3D simulation (left) is consistent with the experimental results (right).

Fig. 3 Observing the temperature profile, it is found that the temperature distribution occurs after the melt passes through the valve pin (left) and continues to the product (right).

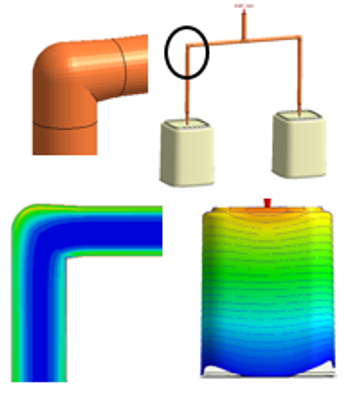

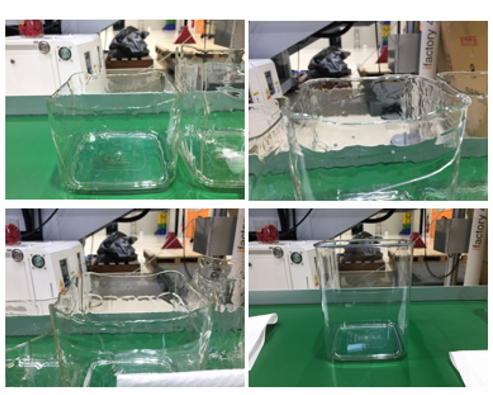

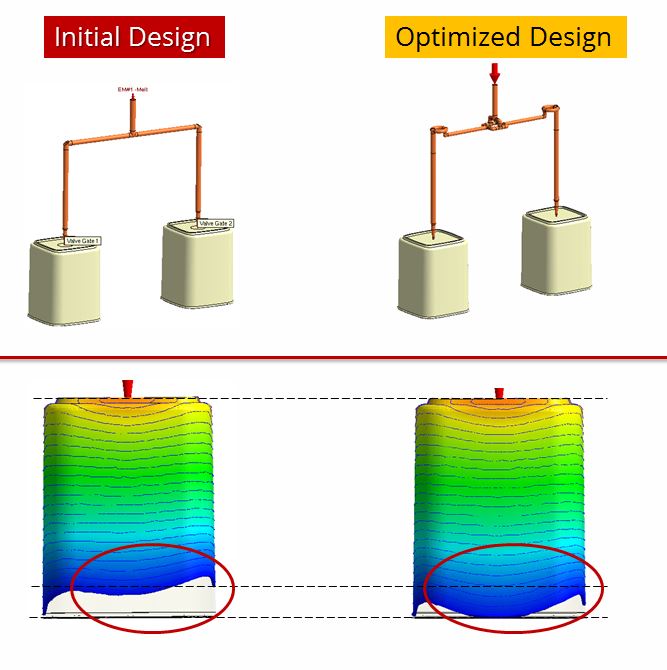

According to the simulation results and experimental verification, it is clearly shown that the valve pin is the key to affect the flow balance. Therefore, Felli tried to quickly verify the results by modifying the valve pin length and removing the valve pin through CAE simulation, they found that the flow balance was significantly improved after the valve pin was removed (Fig. 4). The actual verification also matches the simulation results (Fig. 5).

|

|

Fig. 4 Simulation results with the valve pin removed. |

Fig. 5 The experimental verification |

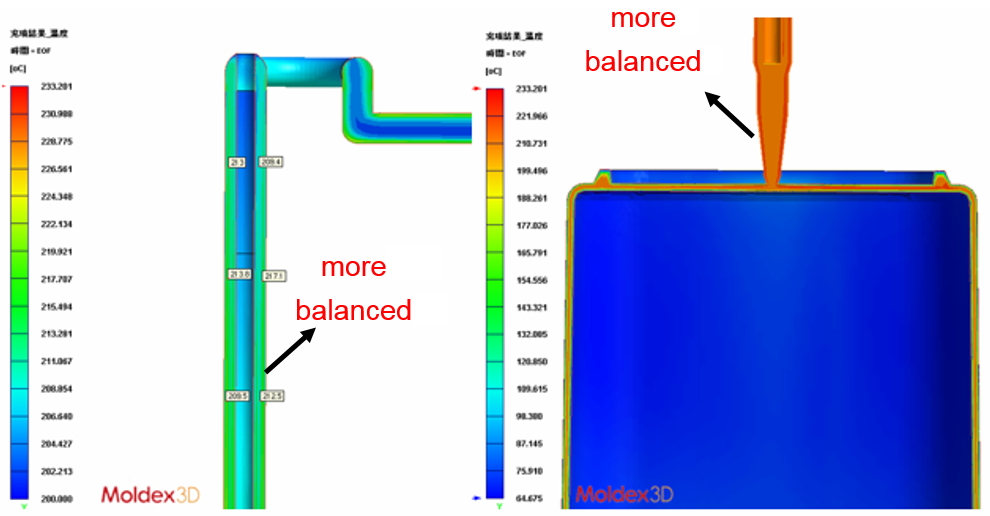

Lastly, Felli optimized the runner design with the melt flipper technology to reduce the temperature difference after the melt passes through the valve gate (Fig. 6), and further improved the flow balance (Fig. 7).

Fig. 6 Through the melt flipper technology, the temperature difference after passing the valve pin is reduced (left), and the flow balance is improved (right).

Fig. 7 The flow imbalance has been obviously improved in the optimized design (right)

Through the analysis of Moldex3D and several low-cost actual verifications, Felli found the real cause of this problem and was provided with a clear direction to make corresponding improvements to the valve pin. After re-validating through Moldex3D, it has improved the problem, reduced the defect rate from 100% to 0%, and reduced the defect rate of the actual production to 0.05%, avoiding the implementation of inefficient countermeasures and generating unnecessary huge costs.

Results

Moldex3D’s Flow and Hexa-based meshing technology enabled Felli engineers to identify flow imbalances and capture accurate, high-resolution temperature distribution in the part. In addition, Felli engineers used Moldex3D to investigate the effect of valve pins on flow balance. The simulation results matched well with the experimental results and demonstrated that the valve pin is the key to improving filling imbalances. With Moldex3D, Felli successfully identified the root cause of the corner effect and optimized the runner design to reduce temperature difference as the melt flow past the valve pin, improving the flow imbalance induced by the corner effect.