When molding ultra-thin wall plastic parts, high injection speed is required to ensure a complete filling of the cavity. However, high injection speed tends to cause high filling pressure which will result in the compression of the free volume of polymer chains; therefore, the viscosity will get higher and the flow resistance will increase. In the packing process, the melt is under the condition of high pressure and low shear rate, hence, the effect of pressure on viscosity will become more critical. Under the circumstances, the pressure distribution will affect the localized viscosity which will subsequently affect the distribution of packing pressure; therefore, the effect of pressure on viscosity in the molding process needs to be considered before conducting a simulation to make sure that the packing, shrinkage and warpage behaviors will be accurately simulated in the later stage.

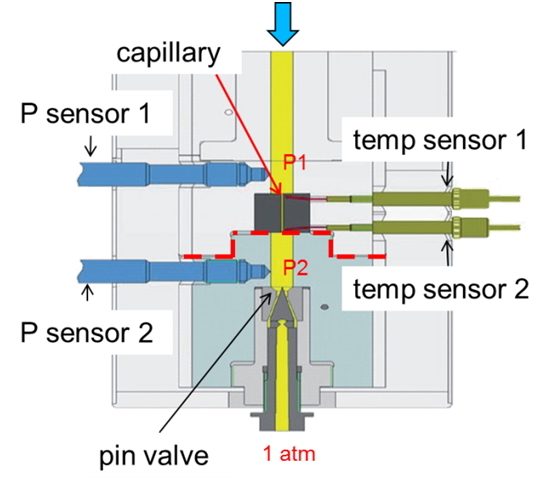

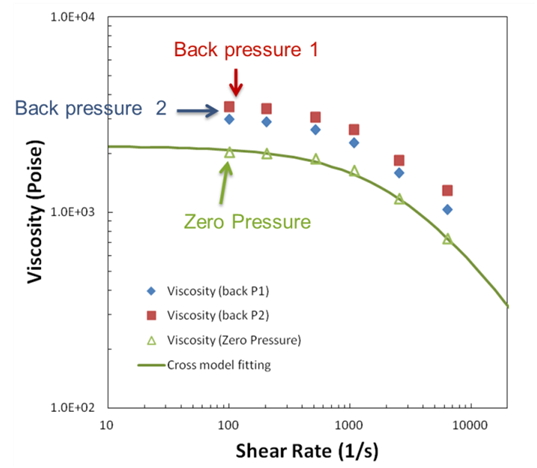

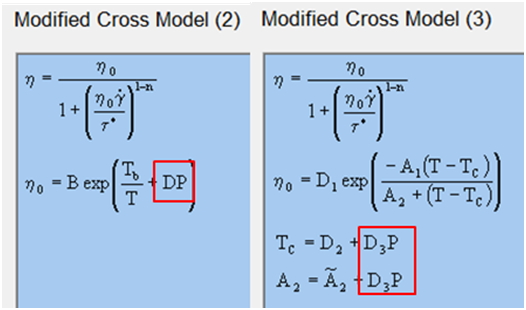

In 2014, Moldex3D Material Characterization Laboratory attained an exclusive U.S. patent on pressure dependency viscosity model and CAE simulation. Through a capillary rheometer (Fig. 1), users can obtain the viscosity property data before running a CAE analysis. The changes of viscosity under different pressures can be measured (Fig. 2) by controlling the opening levels of the valve at the capillary’s exit and applying different back pressures. Two common viscosity models are shown in Fig. 3. The “D” in Modified Cross Model (2) and “D3” in Modified Cross Model (3) are the pressure dependent coefficients. A higher D or D3 value means the viscosity will dramatically increase with higher pressure. According to the viscosity values (Fig. 2) measured by the capillary rheometer under different pressures, the pressure dependent coefficients in the viscosity models as well as the extrapolated viscosity under zero pressure can be obtained. In addition, the theoretical model of pressure-viscosity effect can be referred to U.S. Patent 8,768,662 B2 (Ref. 1).

Fig. 1 The pressure chamber inside the capillary rheometer

Fig. 1 The pressure chamber inside the capillary rheometer

Fig. 2 The plastic viscosity changes under different pressures

Fig. 2 The plastic viscosity changes under different pressures

Fig. 3 The pressure dependent coefficients in two different viscosity models

Fig. 3 The pressure dependent coefficients in two different viscosity models

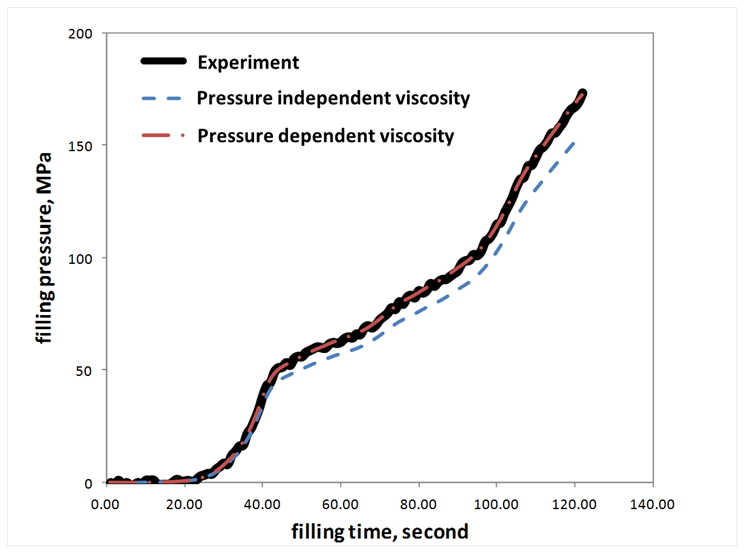

In the following case, the product is a 1.0mm thin part made from PC. Fig. 4 is the comparison of injection pressure curves between the experiment and simulation results including the pressure independent and the pressure dependent viscosity respectively. Under low pressure, the effect of pressure is not obvious. The injection pressure will be almost the same between the two simulations. However, as the pressure increases along with the filling time, the difference between the two simulations will become significant. As shown in the figure, the pressure dependent viscosity simulation result is more consistent with the experiment result.

Fig. 4 The injection pressure curves

Fig. 4 The injection pressure curves

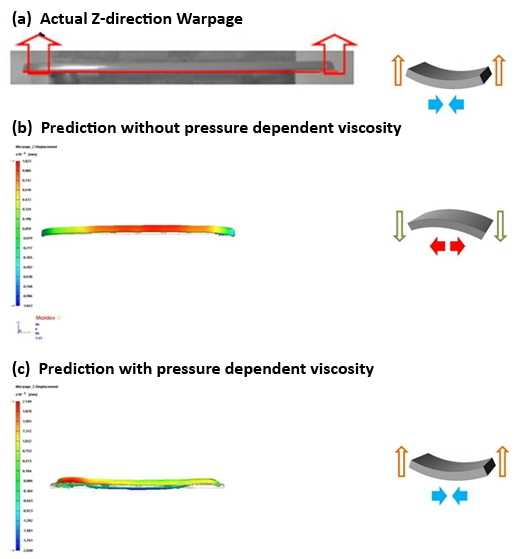

Pressure-viscosity effect does not only affect the injection pressure but also the resistance of flow which will influence the pressure distribution in the mold at the packing stage. The warpage behavior will also be further affected. As shown in Fig.5, considering the effect of pressure dependent viscosity, we can simulate the pressure distribution in the mold more accurately. Therefore, the simulation prediction for the warpage can be more consistent this way with the actual results.

Fig. 5 The comparison between the warpage prediction and the experiment result

Fig. 5 The comparison between the warpage prediction and the experiment result

Through the case above, we can understand the pressure-viscosity effect is critical to attaining an accurate warpage prediction, especially for simulating a high injection pressure molding. The viscosity measured by Moldex3D’s patented material characterization technology is able to help customers attain vital information that can enhance the accuracy and reliability of the simulation results accordingly.

If you are interested in Moldex3D Material Characterization Service, please contact us at chiaoliu@moldex3d.com or visit: https://www.moldex3d.com/support/professional-services/material-characterization

Ref. 1 Rong Yeu Chang, Chia Hsiang Hsu, Hsien Sen Chiu, Shih Po Sun, Chen Chieh Wang, Huan Chan Tseng, Predicting shrinkage of injection molded products with viscoelastic characteristic, U.S. Patent (2014)