Thomas Chiu, Senior Architecture Manager at Product R&D Division of CoreTech System

The Suitability of the Mold Temperature Controllers and Cooling channels

The way to control mold temperature in the injection molding process typically involves the coolant through mold provided by a mold temperature controller, utilizing coolant to maintain the mold at the process temperature. However, every mold’s cooling channels design is different, and purchasing a mold temperature controller for each different cooling channel layout can generate significant costs. So how can one make sure that the existing mold temperature controller is compatible with the cooling channels? Before addressing this question, let’s first understand what a cooling channel system is.

Cooling Channels System

As shown in Fig 1, along the flow path of the coolant, the cooling channels in the mold will distribute the coolant from mold temperature controller to the interior of the mold. After passing the mold, the coolant will then be directed back to the mold temperature controller.

Fig 1. cooling channels

After the coolant enters the interior of the mold temperature controller, it passes through the heat exchanger. Based on the mold temperature that users set, the heat exchanger then adjusts the coolant temperature. Finally, the coolant is sent out from the mold temperature controller using the pump.

We know that flow naturally moves from higher pressure to lower pressure. Along the whole flow path, the coolant has the maximum fluid pressure where it exits the pump. The fluid pressure then gradually decreases through the flow path and reaches its minimum value when returning to the pump.

The Relationship Between Pump and Cooling channels

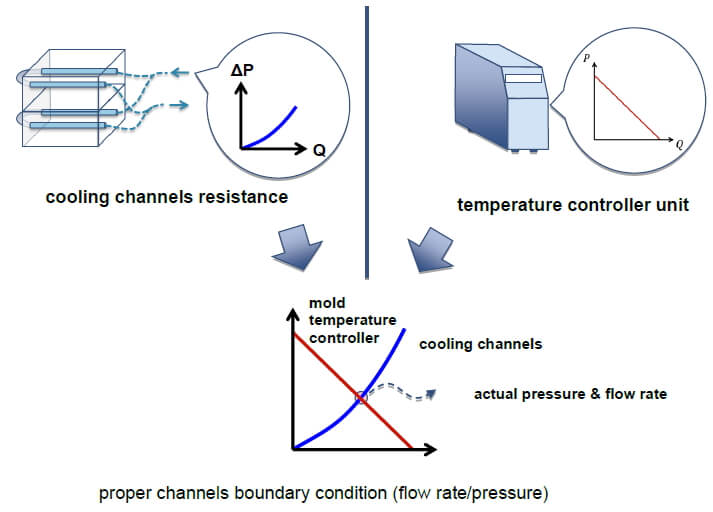

In the specifications provided by mold temperature controller manufacturers, it’s common to find the pump performance curve. This curve illustrates that as output pressure increases, the flow rate decreases, and vice-versa. However, based on pipe theory, with a fixed pipe diameter, a larger flow rate corresponds to a greater pressure drop in the pipe. The combination of pump and cooling channels achieves pressure balance then the value of actual pressure and flow rate can be obtained, as depicted in Figure 2

Fig 2. The relationship between mold temperature controller and mold cooling channels

What Kind of Features Does Moldex3D Equip to Assist

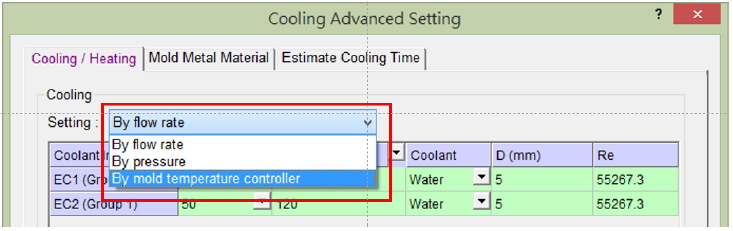

Moldex3D allows users to designate the mold temperature controller for the inlet connecting the cooling channels (as shown in Figure 3). If there’s no flow sensor available, users can design and validate corresponding cooling channel layouts based on the specifications of their existing mold temperature controller. This simulation enables users to know the relationship between cooling channels and the mold temperature controller (refers to Figure 4), providing more reasonable cooling channel inlet conditions without the need to guess the inlet’s flow rate or pressure.

Fig 3. Moldex3D interface for setting cooling channel boundary conditions

Fig 4. Moldex3D analysis of flow rate and pressure relationship

Conclusion

For mold temperature controller manufacturers, it’s impractical to understand the cooling channels for each customer’s mold design. Similarly, for each customer, purchasing different temperature controllers for each mold isn’t cost-effective. Therefore, in most cases, compatibility between the mold design and temperature controller is estimated based on mold, part sizes and temperature requirements. Fine-tuning of the mold temperature controller is then done according to on-site temperature conditions for more precise adjustments. However, some cooling channel designs are special, particularly conformal cooling designs. These designs are often not a simple, long cylindrical water pipe, making it less straightforward to assess the compatibility of mold temperature controllers based on experience.