STUDENT CATEGORY

SPECIAL PRIZE WINNER

Project Name: Design of a Plastic Bike Rear Derailleur for Metal Replacement

School: University of Massachusetts Lowell

By Davide Masato, Leonardo Piccolo, Fabian Ullrich

Summary

Summary

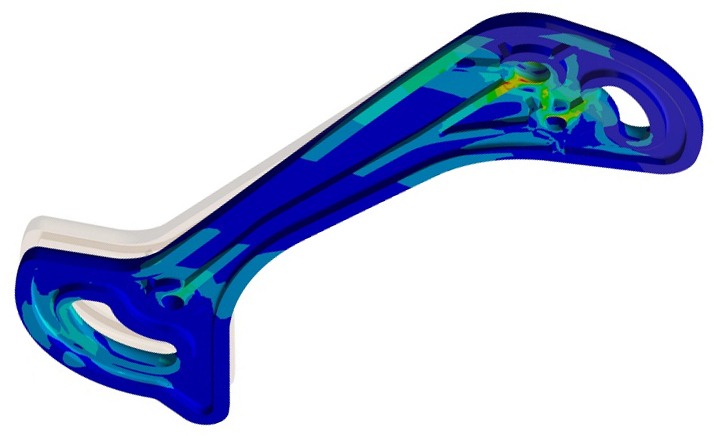

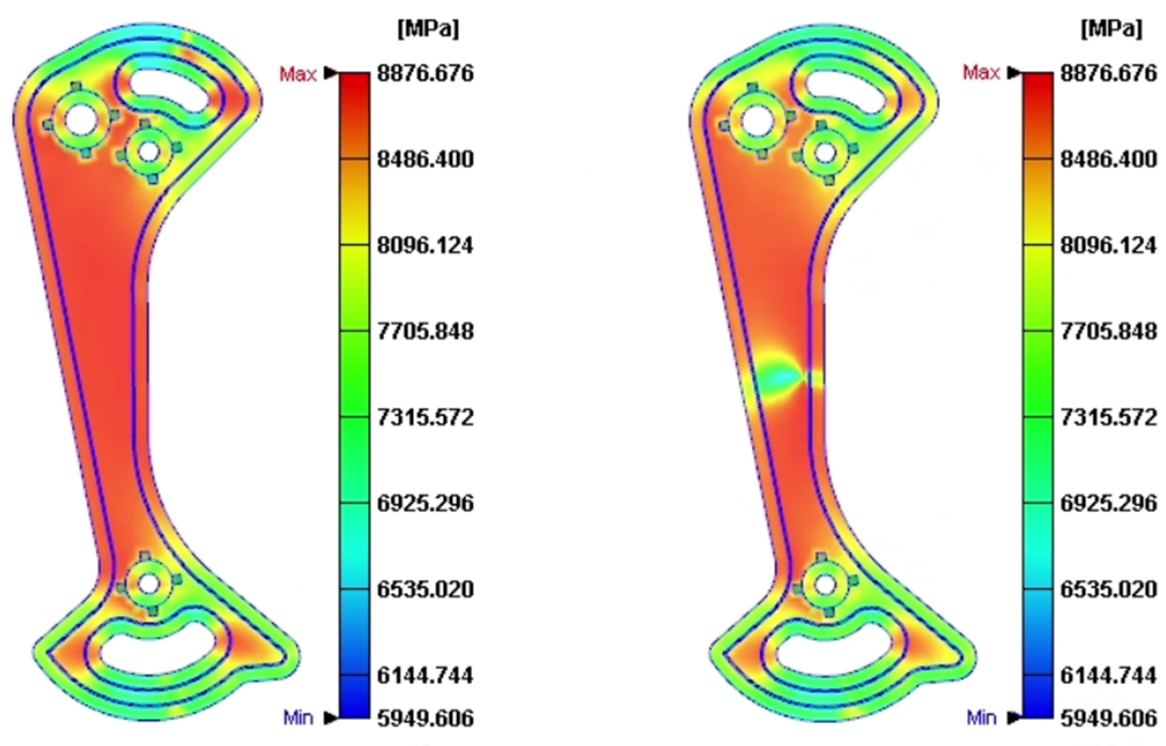

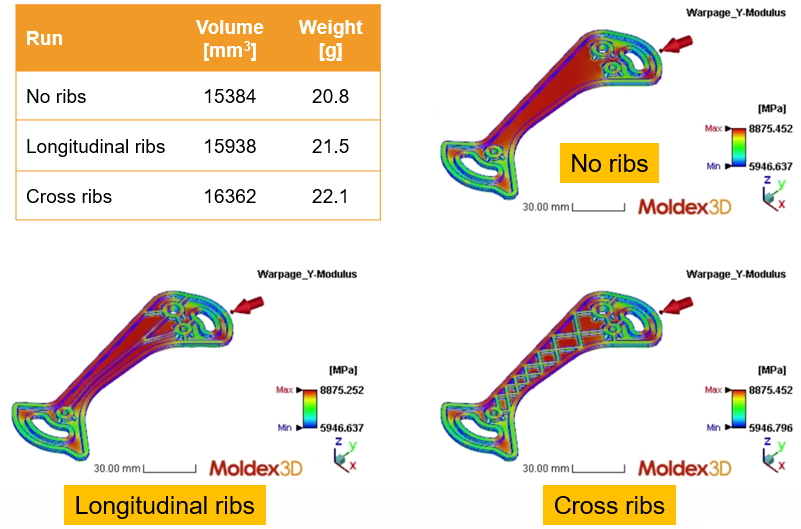

Rear derailleurs are structural components for bike gears. The component is usually an assembly of two metal parts that hold the chain in between. Our Team here proposes to use process and structural simulation to re-design the component for manufacturing with a fiber-reinforced resin. Our approach includes re-design and optimization of the part for injection molding, and structural analysis using the CAE results as inputs for the orthotropic material properties. Coupling the process simulation with the structural FEA allow for advanced optimization of part and mold design.

Challenges

Challenges

- Optimization of part and mold design for a fiber-reinforced structural component

- Minimization of part deflection as a function of fiber orientation

- Control of process parameters for warpage optimization and minimum deflection

Solutions

Solutions

The UMass Lowell team uses Moldex3D to study the correlation between part design, mold design, study fiber orientation, and structural properties. The software is used to validate fiber content and resin selection from a processing and functional perspective. The approach demonstrates the effectiveness of combining process simulation and structural simulation for redesigning products with plastic reinforced polymers.

Benefits

Benefits

- Effective part redesign with plastic and validation of structural properties against original design (metal)

- Thanks to the FEA interface the process-related material properties can be used to accurately predict the mechanical performance of the designed part

- Optimized fiber content and orientation through optimal mold design

- Avoided costly mold prototyping and reconstructions through coupling of processing and structural simulation

Products Used

Products Used

– Flow

– Pack

– Cool

– Warp

– Fiber

Meet the Team

Meet the Team