COMPANY CATEGORY

SPECIAL PRIZE WINNER

Project Name: Warpage Optimization of Automotive Car Roof Cartridge Part

Company: NetShape / Shape Corp

By Kevin Roberts, Prasad Gunjikar, Jonathan Wolff

Summary

Summary

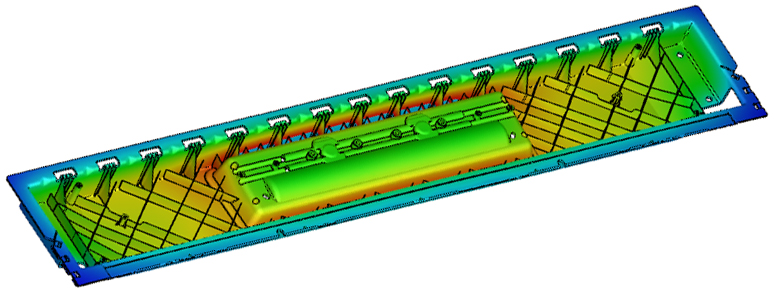

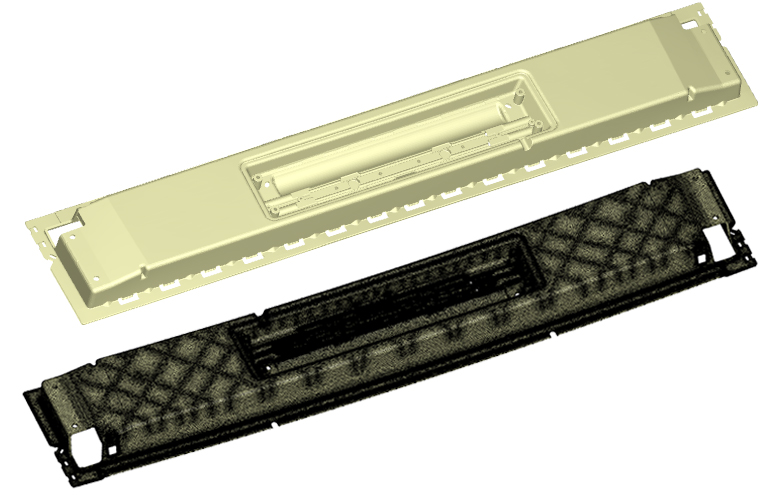

In case of automotive manufacturing due to current need of weight reduction, most of the steel parts are getting converted into plastics. And the main problem of the plastic part is warpage due to its size and thickness.

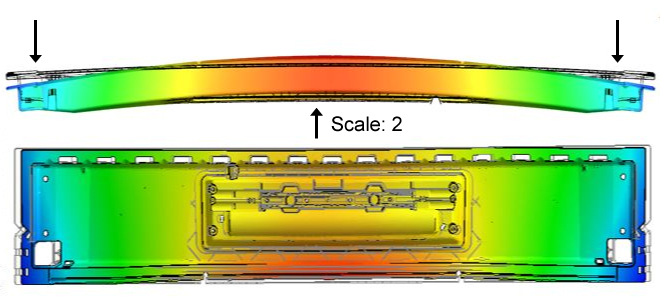

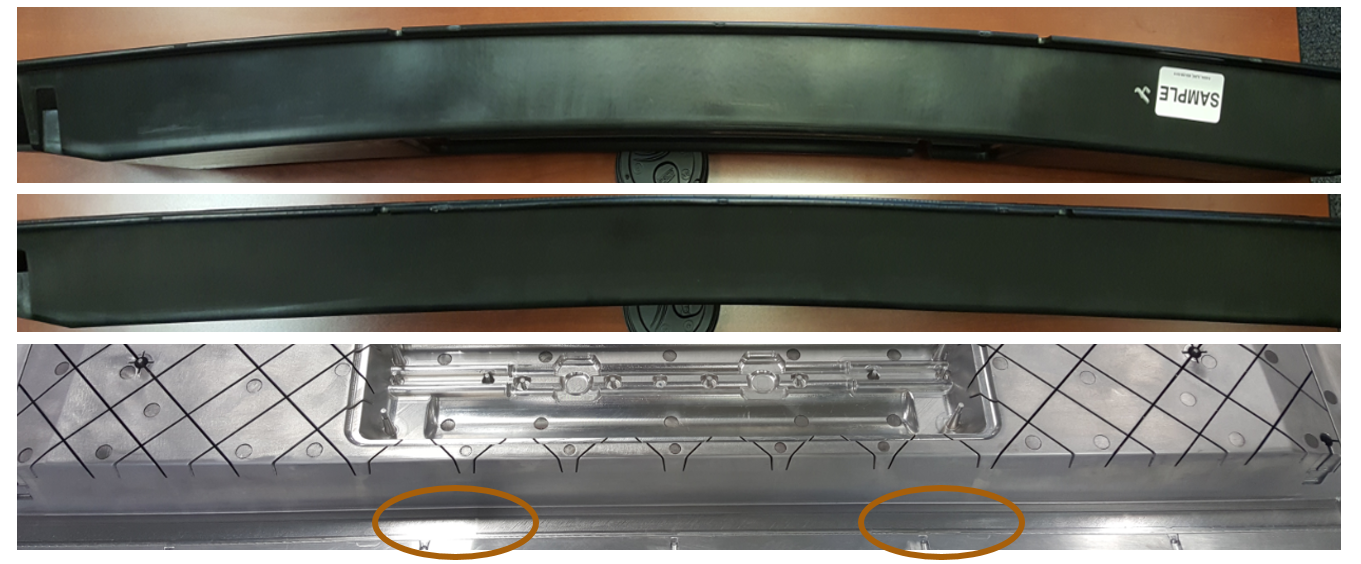

In this case, our process and method of redesigning the part to reduce warpage is based on the reverse deformation technique. Moldex3D solutions enable us to predict and solve warpage by exporting the inverse model from software and let tool makers be able to compensate for unavoidable distortion in the mold.

Challenges

Challenges

- Reducing warpage within the gap and flush tolerance for part assembly

- Geometry feature was getting warp around 15 to 18 mm which was unacceptable

Solutions

Solutions

Due to limitation in part modification we have very limited scope to reduce warpage. Hence, Shape Corp chooses to pre-warp the part with scale1 to reduce warpage at overall.

Benefits

Benefits

- Reduce machine tonnage

- Avoided the fitment issue

- Reduce warpage

- Improve overall productivity

Products Used

Products Used

- Moldex3D Advanced Package

– Flow

– Pack

– Cool

– Warp

– Fiber

– Designer BLM

Meet the Team

Meet the Team