Shadow Polymer Industries, founded in 1996 by Robert A. Hickman, is a full service design, engineering, optimization, and analysis group dedicated to state-of-the-art product development and advanced manufacturing. They surpass their client’s expectations by employing a unique combination of manufacturing experience with advanced simulation technologies to optimize performance and increase profitability.

Shadow Polymer Industries’ customers vary in size from start-up operations through multi-billion dollar corporations. Shadow has an industry leading team of employees and partners to fulfill many needs in a variety of industries. Industries presently serviced by Shadow include: Consumer Products, Automotive, Aerospace, Electrical Components, Food Service, Wireless Communications, Industrial, Medical, Seating, Packaging and Construction. Shadow has utilized numerous software packages over the years for mold flow analysis and has come to rely on Moldex3D for its precision and accuracy of results. Having confidence in the software utilized is of the utmost importance to Shadow’s team, and they have continually proven year after year that Moldex3D is the most reliable, accurate and real-world based simulation software available in the market.

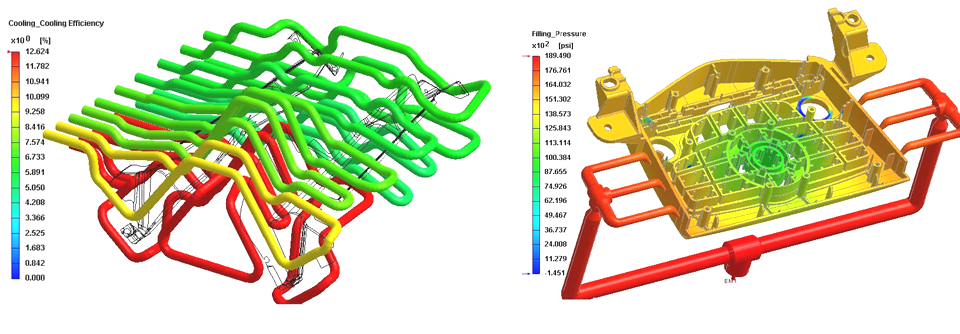

By using Moldex3D software, Shadow has been able to more efficiently and accurately deliver critical information to customers in need thereby insuring that the client is fully aware of the product’s capabilities and limitations before the tooling and manufacturing phases begin. Over the years, Shadow has also been able to incorporate Moldex3D into the process of streamlining productivity so customers can save substantially over the course of a product’s life cycle.

“With nearly a decade of partnership using Moldex3D, Shadow has experienced higher customer satisfaction and increased profitability for our clients,” explains Robert Hickman, President and Chief Engineer of Shadow Polymer Industries. Mr. Hickman continues, “Through the continued partnership with CoreTech and Moldex3D, Shadow remains confident of its ability to provide real-world solutions to our customers by improving product performance, reducing cycle times, and streamlining the manufacturing process. By doing this Shadow is able to continue its upward growth while maintaining a high customer satisfaction.”