Hoffer Plastics Corporation is a family-owned, custom injection molding company founded in 1953 by Robert A. and Helen C. Hoffer. In the last 59 years, Hoffer Plastics has grown to operating over 103 injection molding machines ranging from 85 to 600 tons and is located in a 365,000 sq. ft. facility in South Elgin, Illinois. Outside of their domestic facility, Hoffer Plastics has a minority ownership in The Intec Group’s operations in North America and Asia and has the ability to manufacture at 6 facilities internationally. Among Hoffer Plastics’ many areas of expertise is MuCell®, Gas assist, In-mold labeling, insert molding and two shot (two material) molding along with all secondary operations needed to complete any program’s needs. Hoffer also has 3 tool rooms on site as well as 27 full-time toolmakers to support all tooling needs.(www.hofferplastics.com)

Since 2007, Hoffer has utilized Moldex3D’s engineering simulation software on all new programs to define flow of the plastic and in critical applications warp. Over the last 5 years, Hoffer has run over 600 simulations and gained confidence in the results which supports our continued utilization of the software –Charles Webster, Product Development Engineer at Hoffer Plastics

Case Study

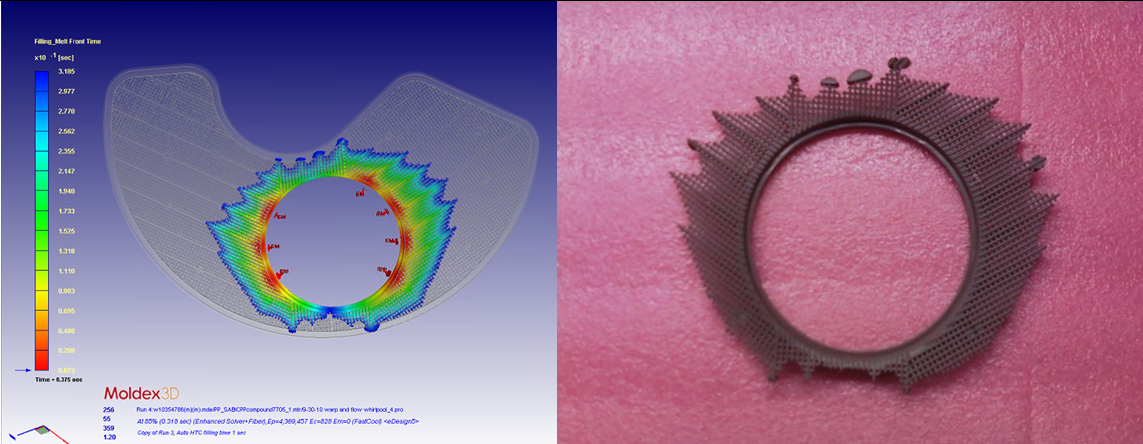

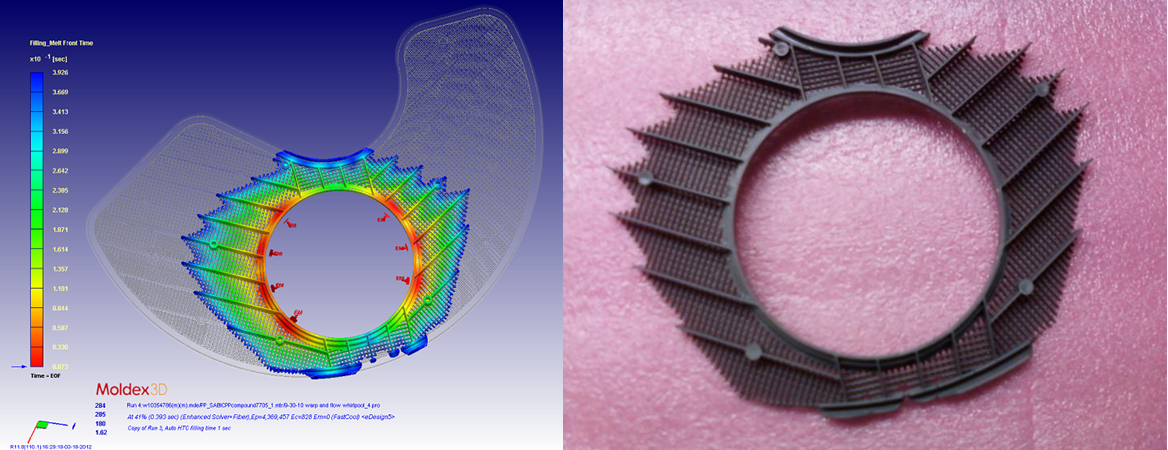

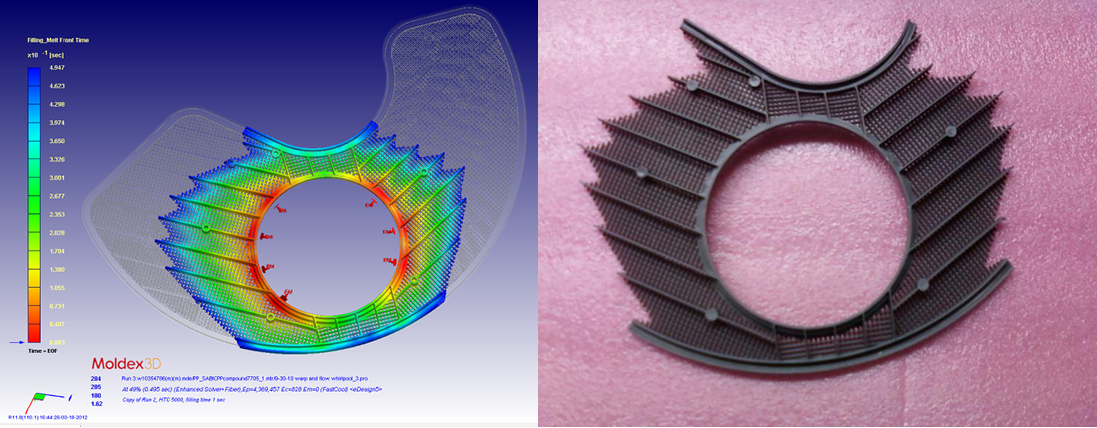

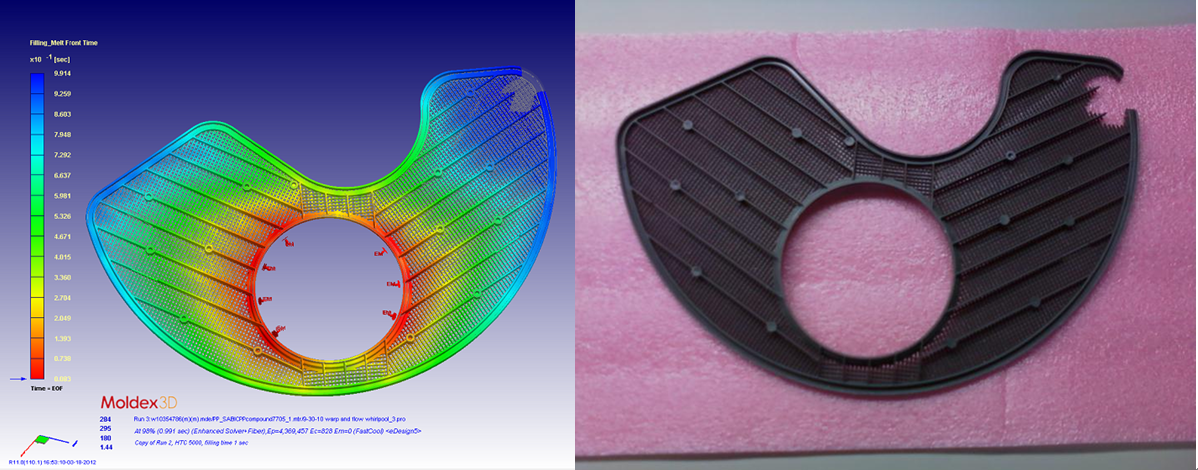

The dish washer filter is now currently on the market. Two materials were evaluated for warp and fill. In previous designs holes were round and cored out from one side. Hoffer’s experience with speaker grills and a patented design for manufacturing square holes was utilized. The filter must maintain flatness in both assembly and in application. No residual in-molded stress can be tolerated as in application the water temperature can reach as high as 180 degrees F. Because of this a flow and warp analysis has to be done in conjunction with the mold design. The cooling line must be modeled into Moldex3D to allow for correct and accurate results to be at attained.

Simulations of grill-like structures have always been very challenging to injection simulations. Traditional approaches require the grills be modeled as line elements, which are very tedious in modeling and do not provide accurate enough results. Thanks to Moldex3D eDesign, the model can be directly imported from CAD and meshed automatically. All calculations were done at the highest levels of meshing in the Moldex3D eDesign program. The model is extremely large and the resulting STL file was 47.5 megabyte. The flow analysis was done at a level 5 mesh and run on a 64 bit workstation with 16 GB of ram and dual quad processors. All 8 processors were utilized for this analysis for best performance.

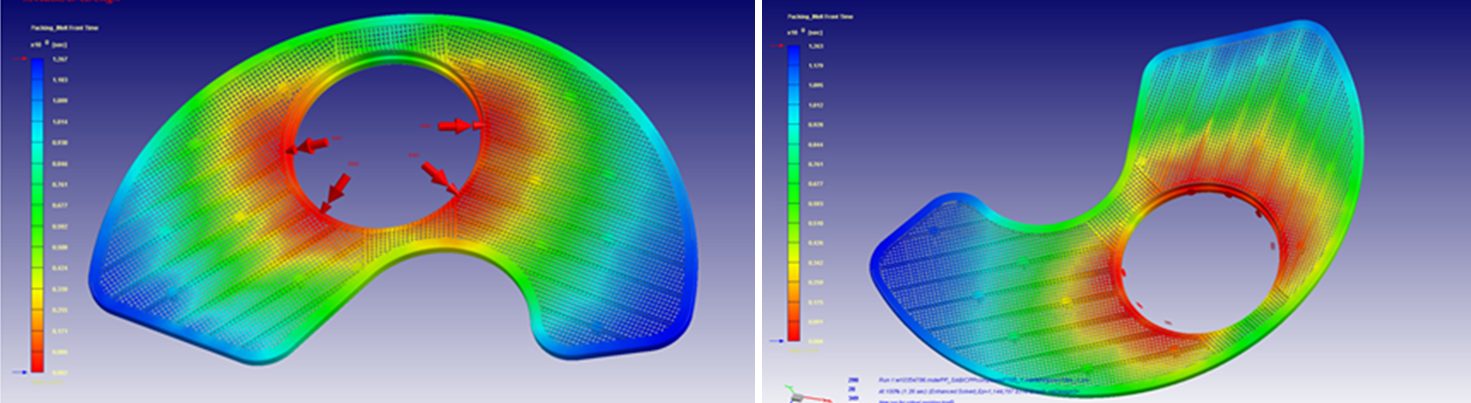

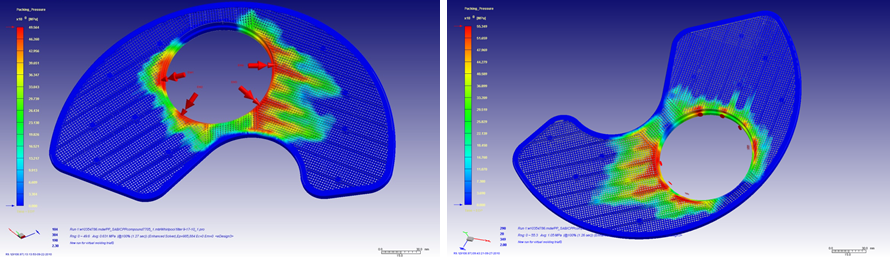

Multiple analyses were done to determine the best number and placements of the gates to attain the best part fill possible with the least amount of post molding warp. Flow analysis was done on a 4 gate configuration and a 7 gate configuration.

Real Life Results:

The prototype tool initially was manufactured in a 4 gate configuration to compare and confirm the flow analysis results. Next the tool was modified to the 7 gate configuration which predicted a better flow and warp prediction. Also of note the analysis predicted a 1.5mm warp which came out very close. Through part adjustments, this was reduced within the part tolerance.

Shown below are the analysis compared to the actual molded parts:

Filling time at 32%

Filling time at 32%

Filling time at 39%

Filling time at 39%

Filling time at 50%

Filling time at 50%

Filling time at 99%

Filling time at 99%

Shown below are the 4 gate vs. 7 gate Melt front time, Pressure and Shear stress analysis comparisons: