STUDENT CATEGORY

THIRD PRIZE WINNER

Project Name: Optimization Design of Conformal Cooling Channel of Injection Mold of LED Lens for Decreasing Residual Stress

School: Dongguan University of Technology

By Zhenzhong Sun, Yan Liu, Lei Chen, Huanyu Liu, Shenggui Chen

Summary

Summary

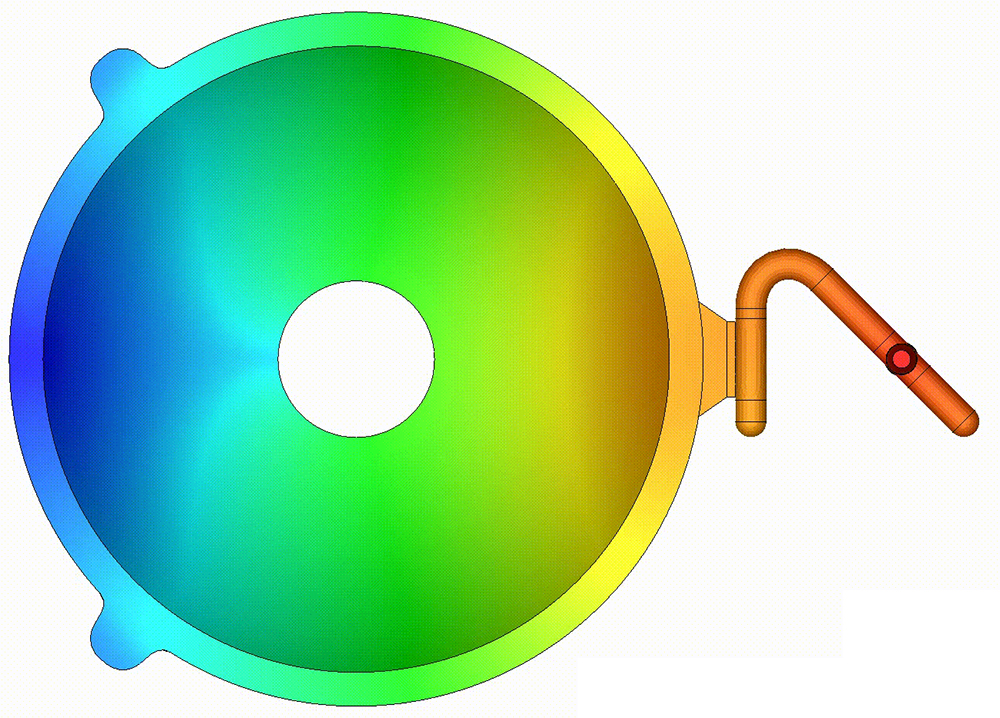

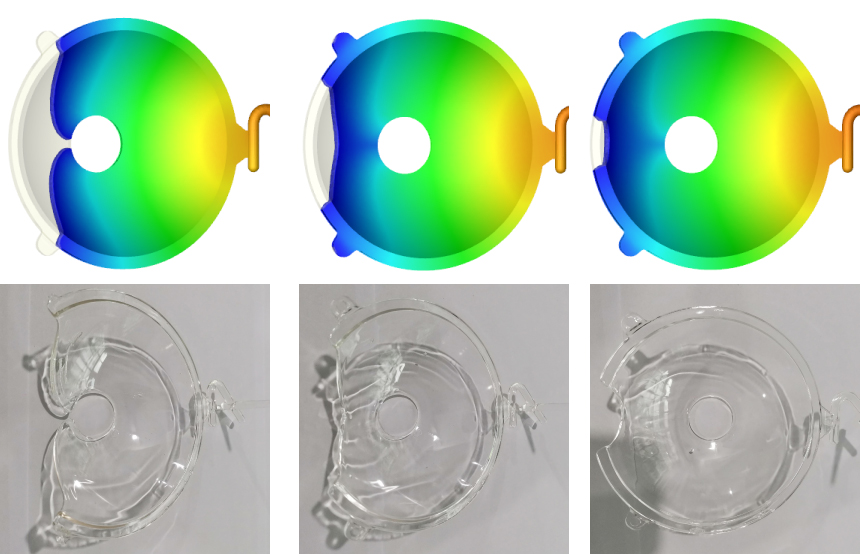

In the Fresnel lens, one side of the lens is a smooth surface and the other side is engraved with small-to-large concentric circles; in short, the serration patterns with equidistance are on one side of the lens. Through these serration patterns, the spectrum bandpass (reflection or refraction) can be achieved in the specified range of the spectrum. The bandpass optical filters in the conventional polished optical device are expensive. Fresnel lenses can significantly reduce the cost. The Dongguan University of Technology used Moldex3D software to optimize the cooling channel design of Fresnel lens and successfully designed a conformal cooling channel to make the temperature evenly distributed after the product was cooled. The orthogonal experiment was also adopted to obtain the best molding manufacturing process to optimize the product molding cycle and reduce the product stress. It will help enterprises to reduce their production cost and enhance production efficiency.

Challenges

Challenges

- Avoid obvious appearance defects such as weld line and flowing mark

- The requirement for surface precision of product is high and the surface roughness is required to be less than 20 nm

- Make the temperature evenly distributed after the product is cooled and reduce the molding cycle

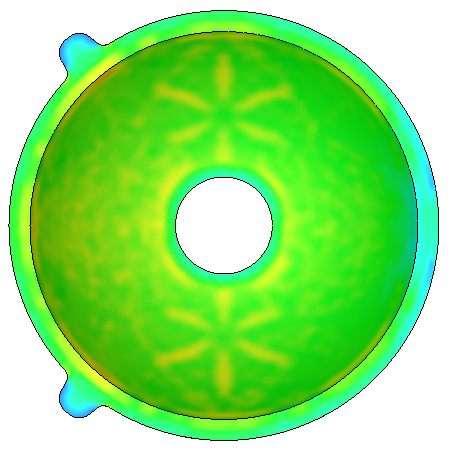

- Reduce the residual stress inside the product

Solutions

Solutions

Dr. Lei Chen et al. used the Moldex3D conformal cooling and stress module to verify the design of a common cooling channel and conformal cooling channel for multiple instances. With the continuous topology optimization, the temperature is evenly distributed after the product is cooled and then Moldex3D is used to predict the optics and residual stress to further optimize the manufacturing process. The best molding manufacturing process and cooling channel can be quickly obtained to significantly shorten the product development cycle and achieve the goal of industry-academia-research institute collaboration.

Benefits

Benefits

- Find the best solution for conformal cooling channel configuration to solve the problem of uneven temperature distribution after the product is cooled

- The product cooling time is reduced from 15 seconds to 13 seconds

- Effectively control the temperature of the weld line and reduce the influence on the appearance of the product.

- Fulfill the precision requirement of dimension for the product

- The residual stress of the product is low and even

Products Used

Products Used

- Moldex3D Advanced Package

– Flow

– Pack

– Cool

– Warp

– Designer BLM

– Stress

– Optics

Meet the Team

Meet the Team