COMPANY CATEGORY

SPECIAL PRIZE WINNER

Project Name: Use Moldex3D To Optimize Product Design & Injection Molding Process

Company: Lite-On Technology Corporation

By Andy WA Chen, Jeffery Lin, Jack JH Wang

Summary

Summary

The ODM factories often encounter issues in product design and development such as the poor appearance of plastic products and the pressure on the cost of molding cycle time. The traditional Trial & Error method for repetitive mold modification has resulted in cost increase and even damage to the molds. The team found out the root cause of the problems with the scientific methods provided by Moldex3D. The analysis data enabled them to find the optimized designs, improve the product quality and have better communications between customers and mold manufacturers.

Challenges

Challenges

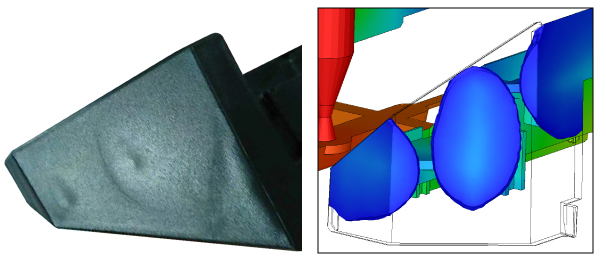

- Analysis and improvement of stress mark

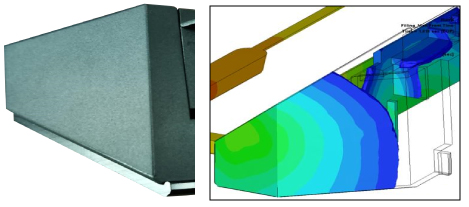

- Improvement of weld line

- Reduce the molding cycle time

- Improvement of the warpage concentricity

Solutions

Solutions

- Verify the position of weld line with melt front time and optimize the gate position and product design

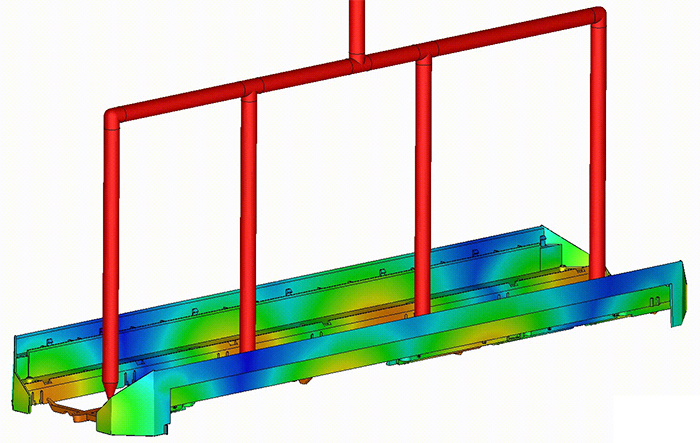

- Analyze the cooling temperature result, find the hot spot, and design the conformal cooling channel

Benefits

Benefits

- Successfully solved the surface mark due to the hot spot issue of the product

- Conduct the computer trial mold and verification through molding analysis, to find a suitable plan for improvement.

- The design of the conformal cooling channel can effectively reduce the cooling time and reduce the cycle time by 50%.

Products Used

Products Used

- Moldex3D eDesign Package

– Flow

– Pack

– Cool

– Warp

– Designer BLM

Meet the Team

Meet the Team