COMPANY CATEGORY

SPECIAL PRIZE WINNER

Project Name: The Application of Moldex3D in the Research of Optical Lens Weld Line

Company: Sun Optical (Dongguan) Opto.Tech Co., Ltd.

By Stone, Bobi

Summary

Summary

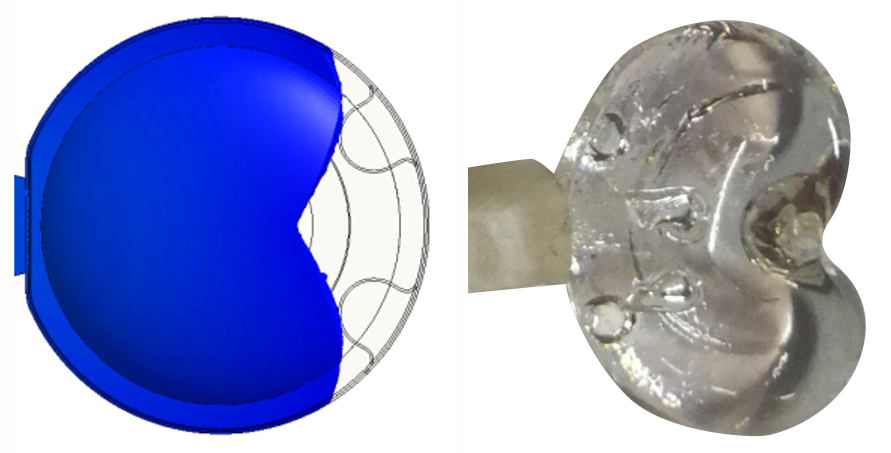

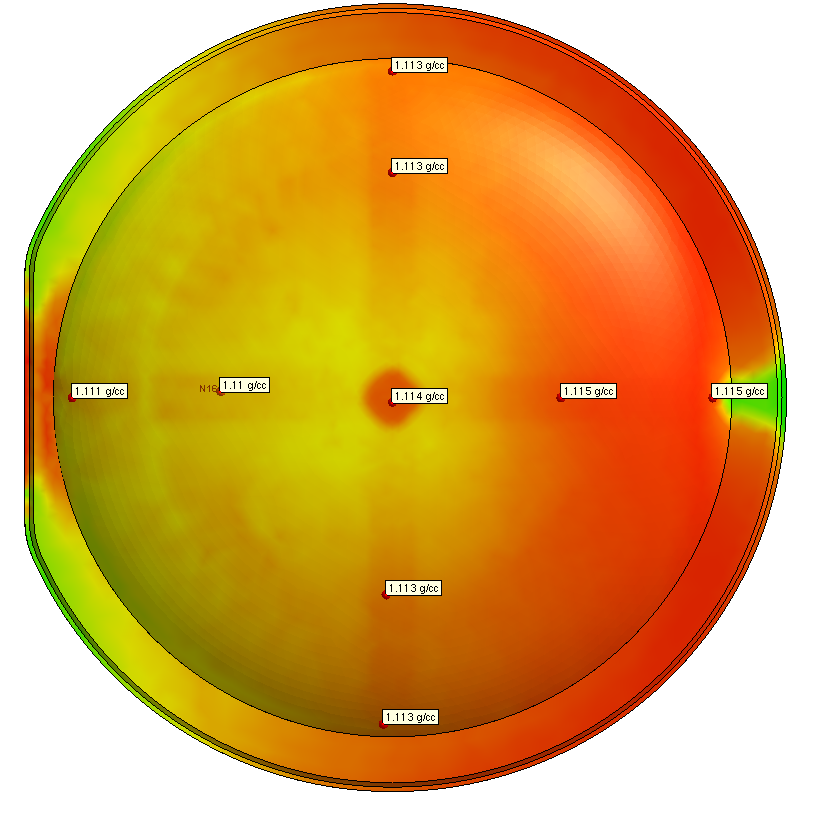

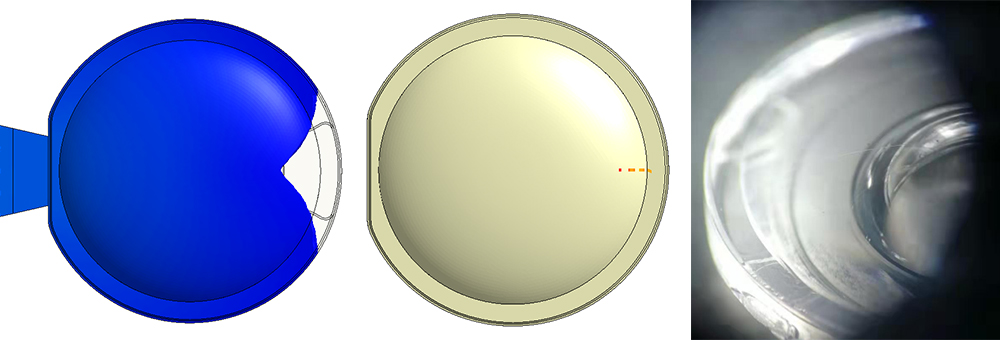

Optical lenses are important components in camera lenses. The camera lens module usually has 1-2 convex-concave lenses and these convex-concave lenses generate a weld line during injection molding, which significantly affects the quality of the optical lens. SUN-OPTICAL OPTO.TECH.CO., LTD adopted Moldex3D molding analysis software to successfully predict the impact of air pressure field on the melt filling flow condition based on the convex and concave lenses to eliminate the weld line of the lens, which is a pioneer in the optical industry and we have applied for several patents.

Challenges

Challenges

At present, the weld line generated during the injection molding is inevitable under the convex-concave structure characteristics of the optical blank lens. The weld line significantly impacts the optical design that is unable to achieve the expected objective. Most of the current manufacturing process for improving the weld line of injection molding product is to reduce the visual sense of the weld line by increasing the material temperature, mold temperature, and enhancement of the injection pressure and injection speed. The utilized manufacturing process approach is relatively simple and the universality is not high. In addition, it is unable to eliminate the weld line to achieve the optimal optical design.

Solutions

Solutions

We used Moldex3D to successfully predict the impact of the air pressure field on the flow behavior to eliminate the weld line generated in the injection molding of optical convex and concave lenses. Moreover, the impact of the weld line on the imaging of the optical lens is improved at the same time.

Benefits

Benefits

- Eliminate the weld line to achieve the best optical design

- The replication is enhanced to increase the surface density of the lens, and thus the film strength is increased by 30%

Products Used

Products Used

- Moldex3D eDesign Package

– Flow

– Pack

– Cool

– Warp

– Optics

– Designer BLM

Meet the Team

Meet the Team