COMPANY CATEGORY

THIRD PRIZE WINNER

Project Name: Application Moldex3D to Hot Runner Design and Improve Injection Molding Efficiency

Company: Sunonwealth Electric Machine Industry Co.Ltd.

By Gary Lin

Summary

Summary

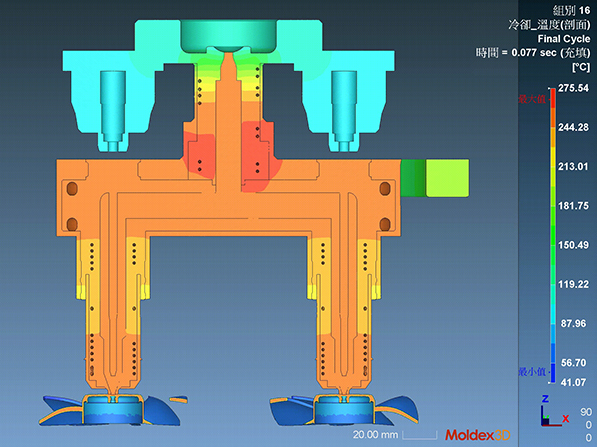

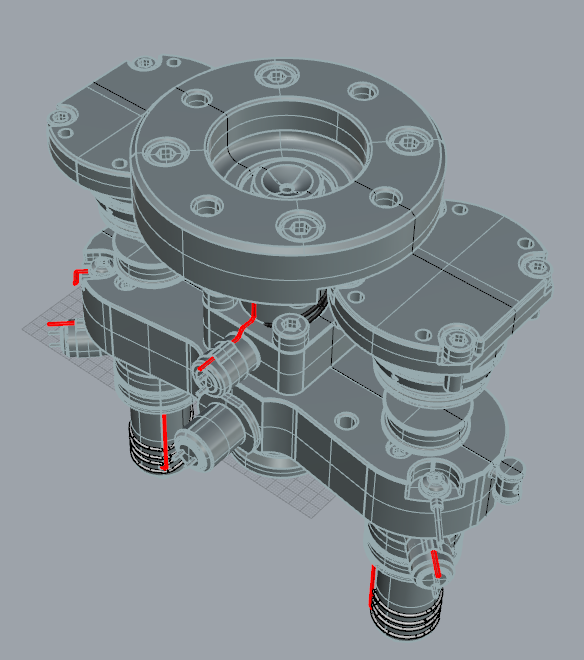

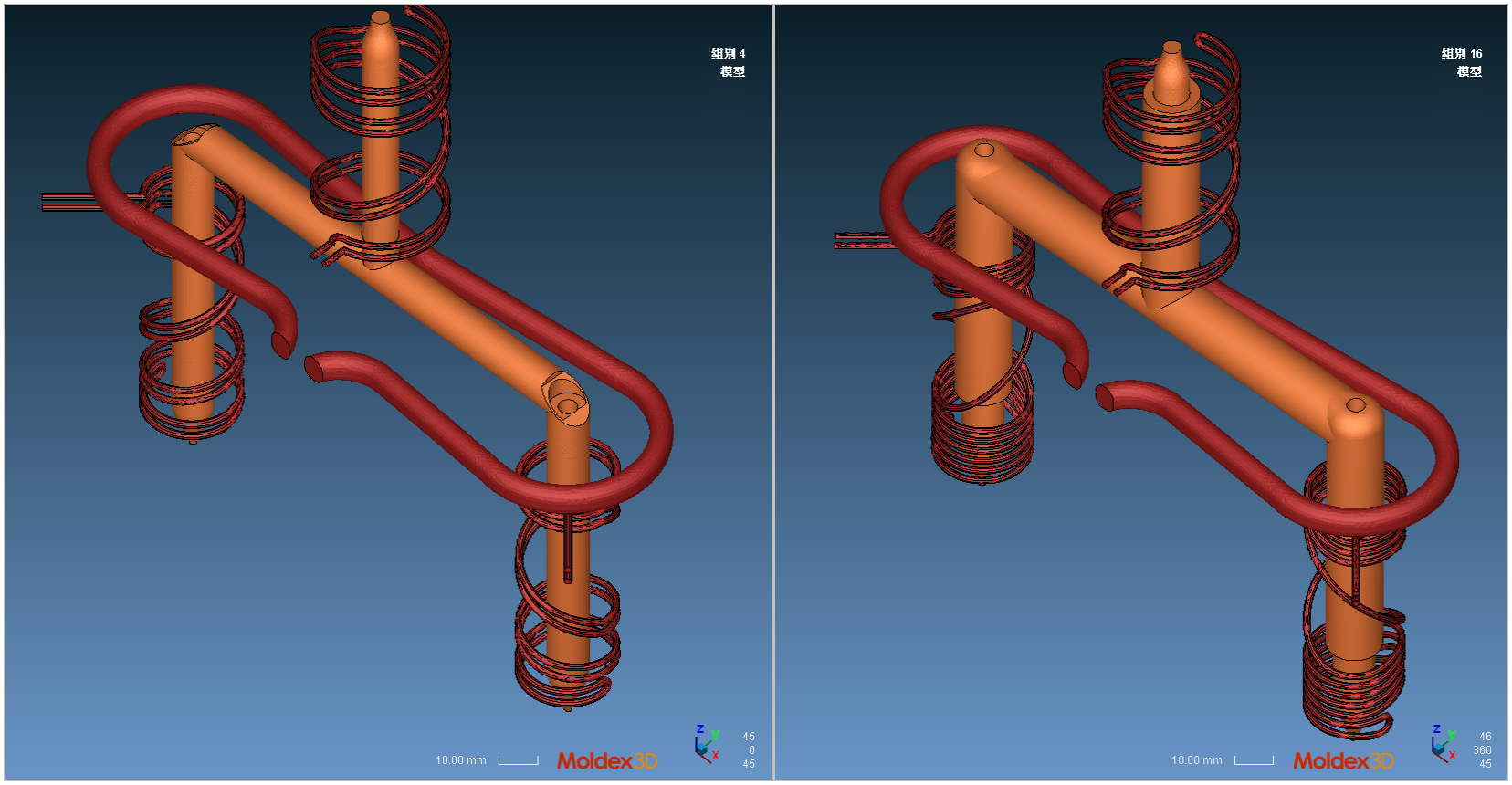

Sunonwealth Electric Machine introduced the Moldex3D Advanced Hot Runner module to deeply study the temperature variation in the hot runner and understand the detailed factors in the hot runner that affect the molding efficiency. Moreover, we improved and optimized the hot runner.

The existing standard hot runner appears to tend to insufficient temperature and the cold plastic part causing flow turbulence, which have affected the injection and resulted in instability. We then modified the runner size for the low-temperature issue and changed the design of coils to improve the cold material situation in the hot runner and enhance the stability and efficiency of product production.

Challenges

Challenges

- Improve the issue of excessive pressure loss in the system

- Improve production efficiency

Solutions

Solutions

In the beginning stage of filling of the original design, the part temperature in the hot runner has appeared to tend to low temperature. When a plastic part with a lower temperature passes through the flow gate, it will affect the injection and even cause a blockage. With the optimized designed, the runner size of the hot runner and design of coils were changed and the injection stability was high and the loss in pressure was low through practical verification, which proved that the modified design can effectively improve the issue of temperature drop in the hot runner and enhance the stability to improve the overall molding efficiency.

Benefits

Benefits

- Improve the issue of excessive pressure loss in the system

- Find out the location of cold area and conduct optimization in accordance with the design change

- Reduce the actual processing and testing costs

- Achieve the optimal result with a minimal design change

- Enhance the injection stability

Products Used

Products Used

- Moldex3D Advanced Package

– Flow

– Pack

– Cool

– Warp

– Designer BLM

– Fiber

– Advanced Hot Runner

Meet the Team

Meet the Team