What is iSLM?

Moldex3D iSLM (Intelligent Solution Lifecycle Management) is an intelligent platform designed to integrate and manage product development data. It centralizes models, simulation records, mold trial results, and process settings into a unified and well-structured data environment, establishing a consistent and reliable foundation for engineering work.

As a simulation intelligence and data management platform, iSLM consolidates engineering information from multiple sources. Users can classify, evaluate, and organize data based on their needs, while directly reviewing 3D models and related simulation results within the platform. By referencing historical projects, design parameters, and recommended process conditions, engineers can more quickly understand problems, compare differences, and make informed design decisions.

Engineering experience accumulated through repeated simulations and validations is systematically organized and transformed into reusable knowledge assets. Through data correlation and intelligent analysis, iSLM generates actionable engineering insights that help teams make faster and more accurate technical judgments. This reduces reliance on individual experience, accelerates development cycles, and improves first-time success rates—resulting in more predictable and stable product quality.

Why iSLM?

Make Data-driven Decisions and Accelerate Problem Identification

Move beyond trial-and-error based on personal experience. By combining simulation histories, mold trial data, and recommended process parameters, every decision is supported by data—shortening analysis cycles and speeding up issue resolution.

Turn Proven Experience into Reusable Knowledge Assets

Capture successful engineering practices as structured, reusable know-how. This lowers the learning curve for new engineers, reduces reliance on individual experts, and improves consistency and stability across development projects.

Four Core Values

AI-Driven Design Intelligence:

Reliable design decisions from simulation data

Leverages historical project data to provide product design and process condition recommendations, helping new projects quickly establish reliable development directions.

Automatically compares similar projects and suggests key design parameters—such as gate location, temperature, and machine settings. Supports both solid and shell models.

Provides real-time responses to operational and design-related questions, with built-in access to both the knowledge base and project database.

Project Automation:

Focus on improvement—not file handling

Allows multiple project folders and knowledge bases to be linked and monitored automatically. The system detects changes in the background and synchronizes updates in real time, including automatic file import, content updates, and uploads—reducing manual maintenance and the risk of version mismatch.

Select multiple projects at once based on custom conditions to classify, tag, and organize data. Scattered information is consolidated into structured categories, making it easier to search, compare, reuse, and significantly improving overall data integration efficiency.

Visual Analytics:

Faster design insights through unified 3D and analytics

Open and review 3D CAD models directly in the browser to understand product structures and mold configurations—no additional software required.

Key quality indicators such as Pass / NG are clearly visualized, enabling quick assessment of overall quality status at a glance.

Compare multiple datasets side by side to quickly identify differences and accelerate root-cause analysis.

Accelerated Simulation:

Streamlined execution, faster results

Batch import project data and use AI-assisted recommendations to configure simulation parameters, significantly reducing manual setup time. Once configured, multiple analyses can be launched simultaneously through automated scheduling, with results returned directly to the database—allowing engineers to focus on design evaluation and optimization while accelerating the overall simulation and validation workflow.

Experience a Comprehensive Smart Management System

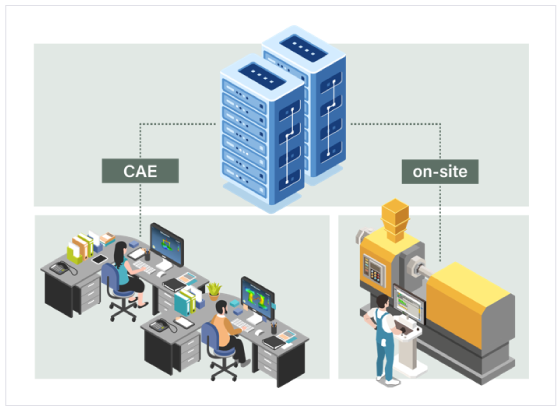

Recreating productivity with iSLM Personal Mode and Server Mode

Personal

An entry-level deployment designed for individual engineers — easy to start, fast to build valuable data assets.

Professional

A collaborative solution built on enterprise R&D standardization, enabling multi-user project sharing, data standardization, and consistent workflows.

Advanced

Enable iSLM to connect directly with injection molding machines for on-site operation and data feedback — integrating intelligent decision-making with real manufacturing to achieve a closed-loop between R&D and production.

Security & Governance

Enterprise-grade data protection to safeguard intellectual property

Private Deployment / On-Premises Architecture

Critical data remains inside the enterprise environment and is not exposed outside the organization. Sensitive product and process data are stored within controlled internal networks, reducing the risk of intellectual property leakage and unauthorized technical disclosure.

Role-Based Access Control (RBAC) with Account Integration (LDAP / SSO)

Access to data is managed through role-based permissions and integrated with enterprise identity systems. This ensures consistent governance policies across users while maintaining secure and auditable access control.

Centralized Data and Version Control

All simulation results and design data are stored in a centralized repository with unified version management. This reduces the risk of misuse, prevents version inconsistencies, and ensures engineers always work with accurate and up-to-date data—minimizing errors caused by version mismatch.