Authored by Ellen Hu, Manager at at Product R&D Division, Moldex3D

Moldex3D Studio integrates the functions of every stage in mold filling simulation. It enables users to automatically fix and generate the mesh, set the material and molding parameters, run analysis, visualize the simulation results, and create analysis reports in a unified platform. This has greatly reduced the time spent on switching among different programs in pre-processing and post-processing. In addition, Moldex3D Studio supports various assistant features and significantly enhances user-friendliness through intuitive interfacing and powerful functions to help users level up the efficiency and quality of their product and mold designs.

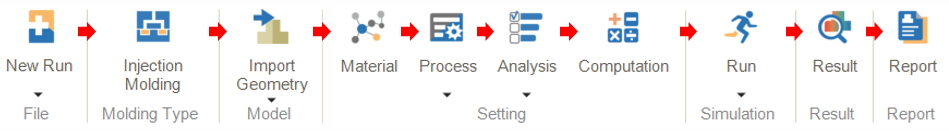

Moldex3D Studio provides a more friendly operation experience and arranges the easy-to-learn operation workflow from the left to the right so that new users can quickly get started from inputting the geometry, setting the cooling system, generating the mesh as well as setting the materials, molding conditions and calculating parameters.

Fig. 1 The operation sequence in the setting interface is from the left to the right

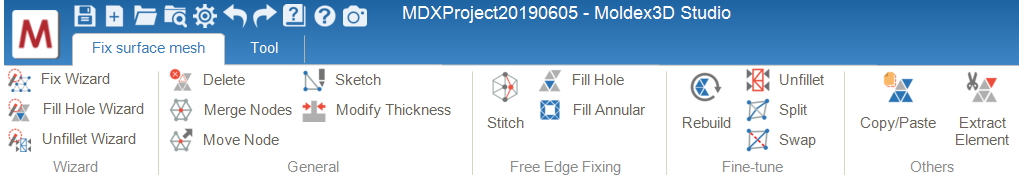

After inputting the geometric models, Studio automatically checks and fixes geometry defects before the surface mesh building. This feature helps reduce users’ time spent on manually fixing the surface mesh, and significantly enhances the meshing efficiency and mesh quality. At the mesh generation stage, Studio can also automatically check the free edges, overlapped mesh or other defects, and fix them with “Fix Wizard”. Studio also provides various mesh editing and fixing tools (Fig. 2) to meet users’ needs of mesh quality, and improve the simulation accuracy.

Fig. 2 Various mesh editing and fixing tools

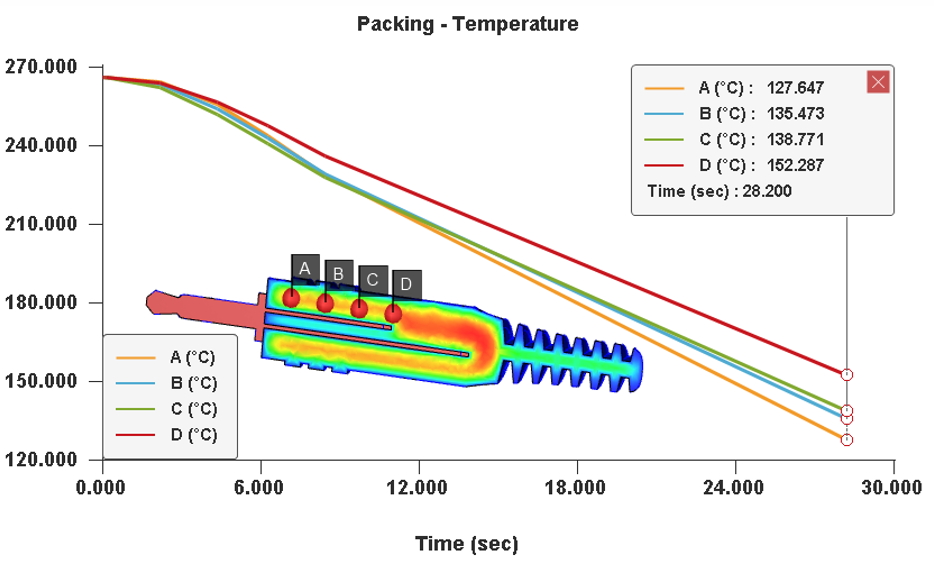

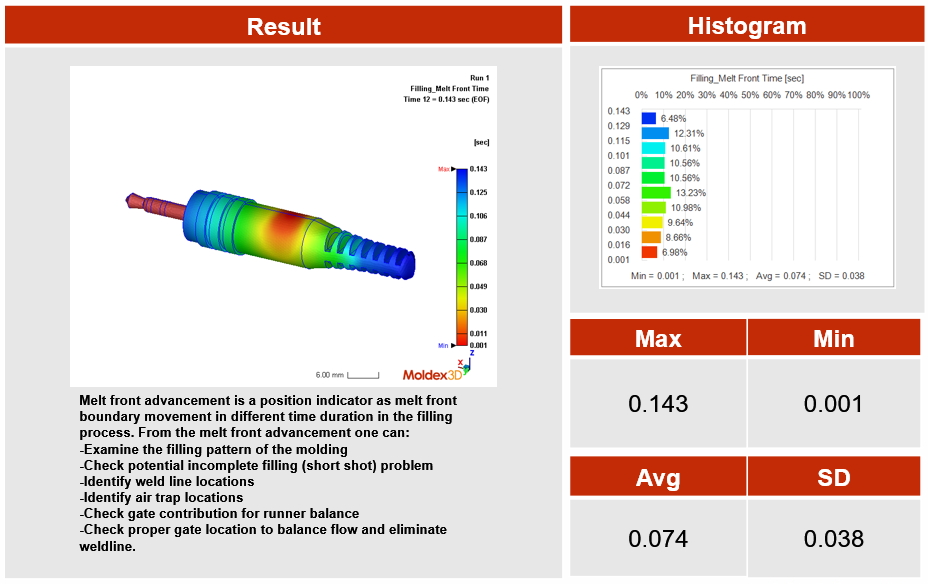

After finishing the analysis, Studio provides analysis result interpretation tools so users can compare multiple analysis results side by side using the multi-window feature. This feature can simultaneously display the same results, same perspectives, and color legend range. The Probe feature can capture the data at specific locations and display it as a curve diagram, in which the analysis results can be shown clearly (Fig. 3). After the analysis, users can generate the report (Fig. 4), customize the report content, reduce the time on making the report, and enhance working efficiency in Studio.