COMPANY CATEGORY

THIRD PRIZE WINNER

Project Name: Application of Molding Analysis to Improve Flow Imbalance and Core Deviation of Single-Cavity Valve Hot Runner

Company: Free-Free Industrial Corp. (Felli)

By Wei-Yang Lu, Nan-Jung Huang, Ping-Hung Chen, Yi-Qing Zhang, I-Hsiang Liu

Summary

Summary

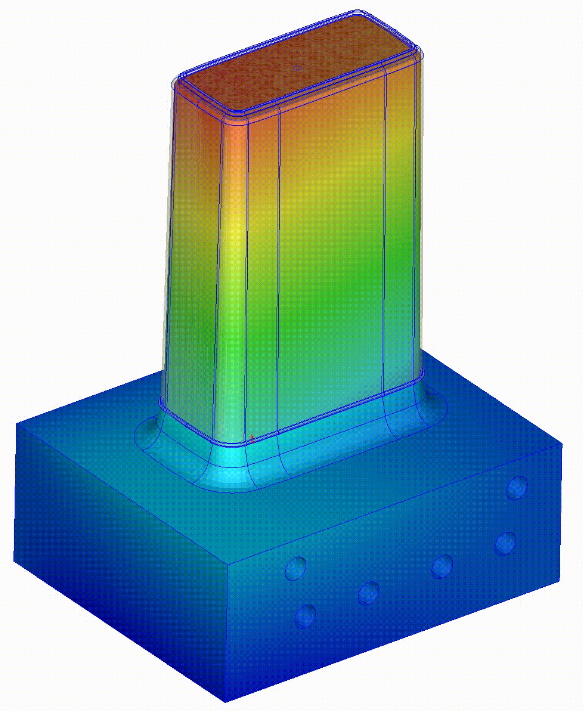

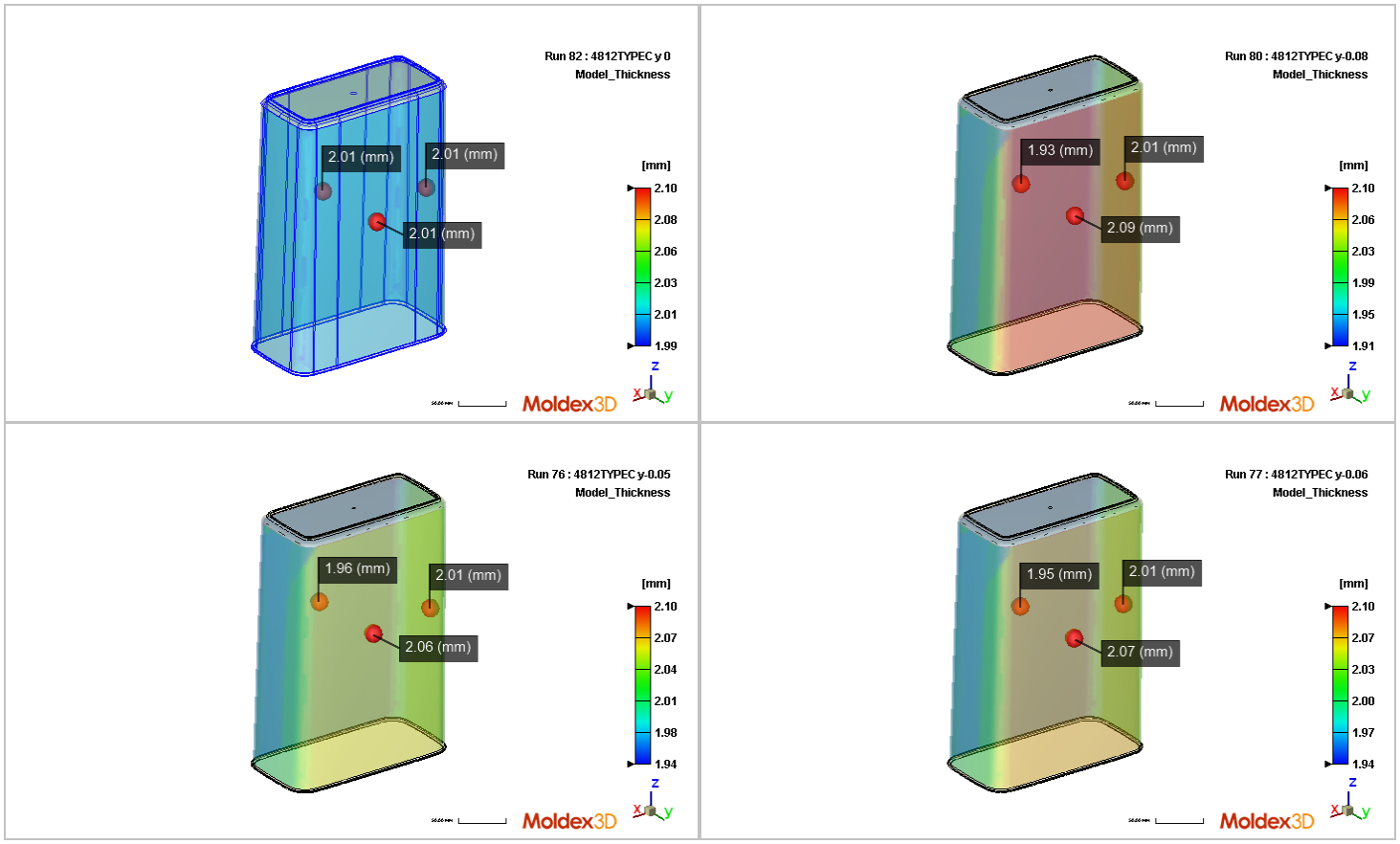

The can body is the main part of a sealed can, but the weld line and air trap will cause insufficient tightness and strength of the product, and thus the weld line and air trap of the can body are important inspection items for the molding quality. Free-Free Industrial Corp. (Felli) uses Moldex3D molding analysis software to conduct optimization for quality design of molds and injection molding manufacturing process, to improve flow imbalance and core shift caused by the Single-Cavity Valve Hot Runner and enhance the productivity and quality stability.

|

|

Challenges

Challenges

- Product appearance defects such as weld line and air trap

- Reduce the thickness shift problem of products

Solutions

Solutions

Free-Free Industrial Corp. (Felli) uses Moldex3D Advanced and Core Shift Module to conduct the fluid-structure interaction analysis for the diagnosis of the core shift issue. Firstly, we used a double valve hot runner to improve the flow balance. Furthermore, we also changed the thickness and temperature of the core and cavity to improve the weld line and flow balance issue of the product.

Benefits

Benefits

- Effectively optimize the flow balance and control the core shift issue

- Eliminate the weld line and prevent the product from being cracked

- Fulfill the quality requirements of product appearance

- The production yield rate is enhanced from 0% to 99.7%

Products Used

Products Used

Meet the Team

Meet the Team