COMPANY CATEGORY

SPECIAL PRIZE WINNER

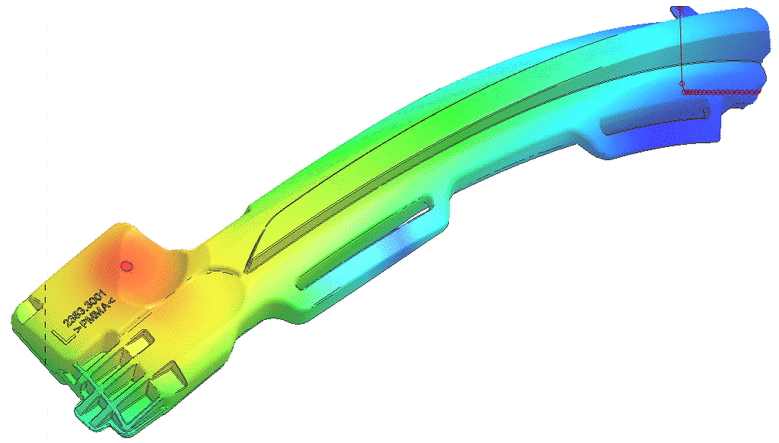

Project Name: Cycle time reduction of Side-Turn Indicator (STI) Lens with Reverse Warp Design

Company: Motherson Australia Pty. Limited

By Michael Ellis, Praveen Kelath

Summary

Summary

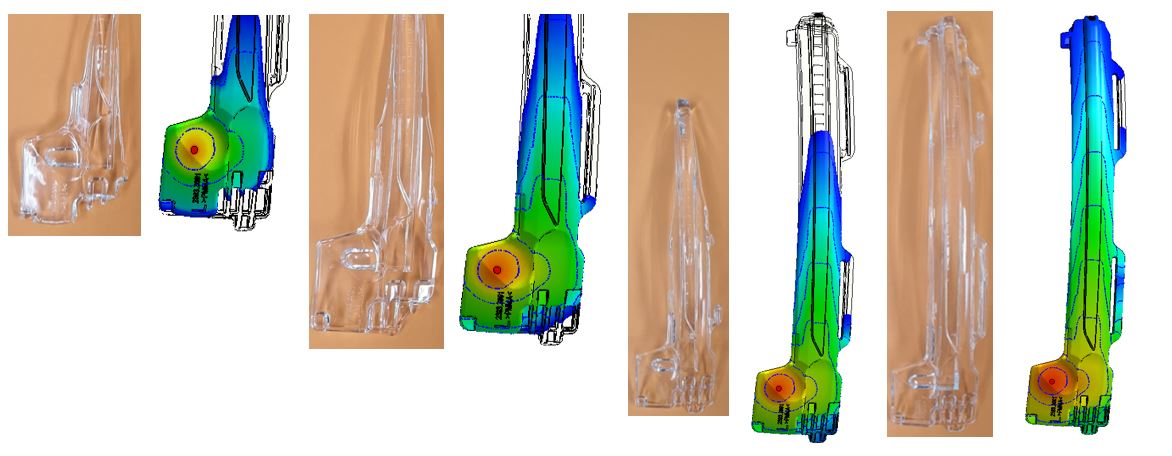

Side-Turn Indicator Lens integrated with light pipe has a very complex optical design with a variable wall thickness from 1.8 mm up to 12 mm which makes the molding process complex. With the help of Moldex3D we are able to effectively design the part with transitions from different wall thicknesses, flow leader, avoid critical air traps and flow marks, design cooling channel, avoid ejection at soft spots, tool inserts with proper vents, profile the packing pressure to attain uniform pack density on the part and effectively design a reverse warp part to compensate the warpage and reduce the longer cooling time.

Challenges

Challenges

- Reduce warpage by process optimization and adopt the reverse warp design if required

- Bring down the cycle time to improve productivity

- Optimize the packing profile to achieve the desired pack density for the thick light pipe

- Ensure no hesitation/short-shot at the thin sections of the lens with a slower filling time thus providing a wider process window for molding. Design a flow leader if required

- Avoid air traps and sink marks on the visible surfaces

Solutions

Solutions

- Use melt front time result to find hesitation and air trap, then design flow leader and enlarge rib thickness to eliminate problems

- Use air trap indicator to consult costumer to change draft angle

- Use cooling molten core to find the best time to eject

- Revise packing pressure profile to reduce warpage

Benefits

Benefits

- Reduced cycle time by 47 s (40%) by adjusting the warp in over-bend design

- Warp on the part is improved and compensated accurately with reverse warp design

- Shrinkage is accurately predicted and reduced by 60%

- Air traps and hesitations eliminated. Effective flow leader added

- Pack pressure profile optimized to achieve uniform pack density and at the same time limiting the clamp force within the in-house machine capacity

- Sink mark improved by 62%

- Avoided costly mold reconstructions and improved the overall productivity

Products Used

Products Used

- Moldex3D Advanced Package

– Flow

– Pack

– Cool

– Warp

– Designer BLM

Meet the Team

Meet the Team