STUDENT CATEGORY

SPECIAL PRIZE WINNER

Project Name: Study on the Effect of Process Parameters and Mold Structure on the “Whiten Spot” on ASA Products Surface

School: Shanghai Jiao Tong University

By Guanghong Hu, Qingsong Cao , Kaiyan Wang

Summary

Summary

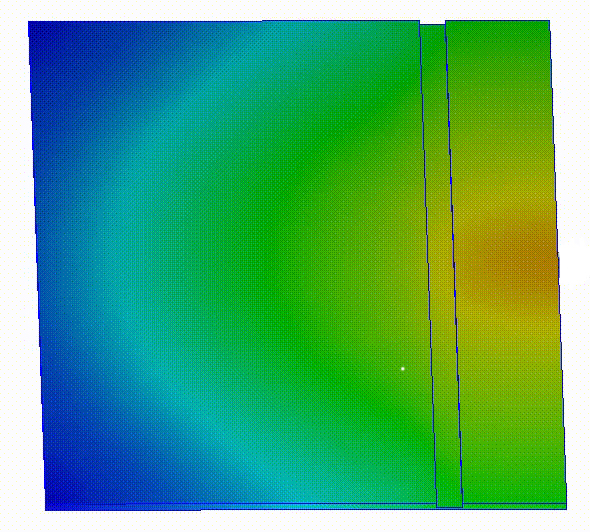

The “white spot” often appears nearby the flow gate in the product molding process of ASA, which affects the appearance and quality of the product. The occurrence of this “white spot” is obviously related to the molding process and the structure of the mold. This project adopted Moldex3D software to simulate the molding process and integrated the practical experiment to study the relationship between the molding process, the structure of mold, and the “white spot” on the surface of ASA products.

Challenges

Challenges

- The air mark and uneven color state often appear nearby the flow gate and in the flowing concave area in front of the flow gate, which is the “white spot” and the reason for causing this issue is complicated and difficult to be solved.

- Among the complicated factors of occurrence of “white spots,” we study its causes and improvement methods through simulation

- We created the relationship model between the glossiness and parameters of the manufacturing process, as well as optimized the manufacturing process of molding

Solutions

Solutions

We adopted Moldex3D software to simulate the molding process of ASA products. To find the best molding condition, we simulated and studied the relationship between the occurrence of white spots and various molding condition by configuring the molding parameters for molding simulation such as melt temperature, injection rate, mold temperature, as well as the molding condition such as the size of the gate, product structure. We verified the correctness of the obtained relationship model through practical experiments and proceeded to propose the feasible recommendation and plan for improving the occurrence of “white spots” on the surface of ASA products.

Benefits

Benefits

- Among the various types of molding factors, we efficiently studied the main impact factors for the occurrence of “white spots” on the surface of ASA products

- This project pointed out the correct direction for practical experiments to reduce the workload of experiments, improve the efficiency of experiments, and effectively save human and material resources

Products Used

Products Used

Meet the Team

Meet the Team

The entire team members were very excited to hear this good news.

From being at a loss on how to start the project in the beginning, to gradually clarifying the thinking along the way, I feel the whole process was worthwhile in the end. Apart from the joy of winning, I would like to thank people who had helped and encouraged me in the process.

First of all, I would like to thank my instructor Mr. Guanghong Hu. Mr. Hu kept track of the entire process, from the registration of the competition, the basic learning in the early stage, the project implementation in the mid-term stage, to the data processing and PPT production in the final stage. Mr. Hu has a very high standard of requirements especially in PPT production, however, he patiently guided me to change some of my work using words several times. I feel deep respect for Mr. Hu’s rigorous attitude towards scientific research and work and I am greatly benefited from his guidance.

Moreover, I would like to thank Manager Jim Lee from CoreTech System Co. , Ltd. for the recorded tutorial videos of the Moldex3D series, which are of great help for our learning of software. I encountered some problems in the process of software learning and application, and Manager Lee had helped me a lot. I remember there was once Manager Lee did not get back to my question in time perhaps due to busy at work during the daytime, but Manager Lee contacted me in the evening to teach me many things via a video call. I was really touched and motivated.

I would also like to thank Mr. Liguo Niu from CoreTech System Co. , Ltd. Mr. Niu is responsible for software authorization and he always takes care of the authorization in a timely manner whenever the authorization is required. In addition, Mr. Niu has always paid attention to the progress of the project and encouraged us to continue our work.

Moreover, I would like to thank Engineer Xuehao Hong from CoreTech System Co. , Ltd. who helped me to solve many technical problems, and Ms. Ping Gu who has been patiently assisting us.

In addition, I would like to thank my partner Kaiyan Wang for his assistance in software installation and learning. My senior Weisong Gao also gave a lot of suggestions regarding production and practical experience.

At last, I would like to thank CoreTech System Co. , Ltd. for creating such a platform for everyone to demonstrate their works and thank everyone who participated in this competition. It is the joint effort and collaboration from everyone to enrich this event. Thank you all.