STUDENT CATEGORY

SPECIAL PRIZE WINNER

Project Name: Examining Cooling ─ With an Experiment or by Simulation with Moldex3D

School: Budapest University of Technology and Economics

By Anna Szuchács, József Gábor Kovács, Béla Zink

Summary

Summary

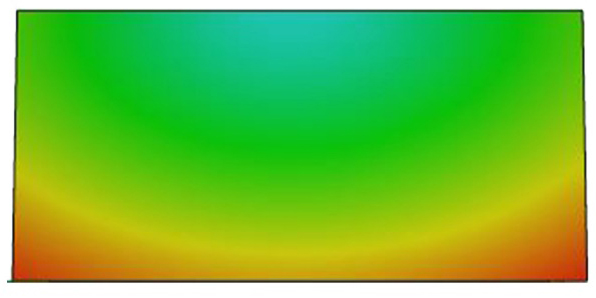

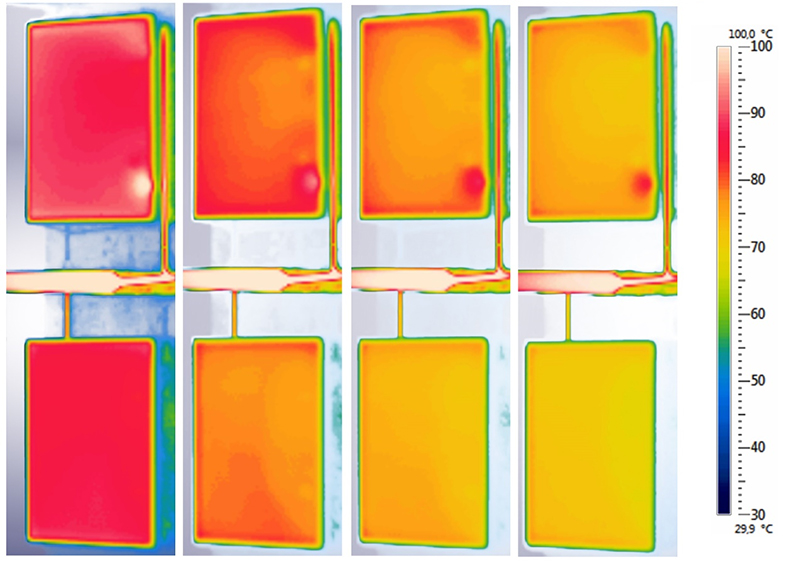

Cooling is one of the most important things in injection molding. Badly constructed cooling systems cause uneven temperature distribution, thus cooling time and warpage increases. Cooling parts with a sharp corner is hard to implement appropriately. Cooling channel optimizations are traditionally costly and take a lot of time. With Moldex3D, we can save money and time, optimization processes are shorter and use fewer resources. In this project, I presented how smart molding can make our life easier, and how much time we can save during a cooling optimization process. I tested 3 different types of mold insert with different shapes of cooling channels traditionally and with Moldex3D. After the tests, I chose the best cooling channel shape for this purpose, therefore I decreased cycle time and warpage.

Challenges

Challenges

- With a traditional cooling channel shape, the appropriate cooling of the roof-top part is hard to achieve

- In the case of inappropriate cooling, cooling time is longer, therefore production is more expensive

- Uneven cooling causes large warpage

- Traditional cooling optimizations are resource-intensive

Solutions

Solutions

The researcher tested 3 different cooling channel layouts, traditional and conformal, built from single or multi-materials. With Moldex3D, cooling optimizations are faster, easier and use fewer recourses. We can see inside the cavity during the processes, thus we can examine temperature distribution and the efficiency of cooling. With conformal cooling channels, cooling is even and we can achieve a shorter cycle time and smaller warpage.

Benefits

Benefits

- Cooling optimization time decreased by 80%

- Material usage decreased from 5 kg to ZERO

- Energy usage decreased

- Warpage decreased by 30%

- Cooling time decreased by 18%

Products Used

Products Used

- Moldex3D Advanced Package

– Flow

– Pack

– Cool

– Warp

– Designer BLM

Meet the Team

Meet the Team