Jill Chen, Administrator at Product R&D Division of CoreTech System (Moldex3D)

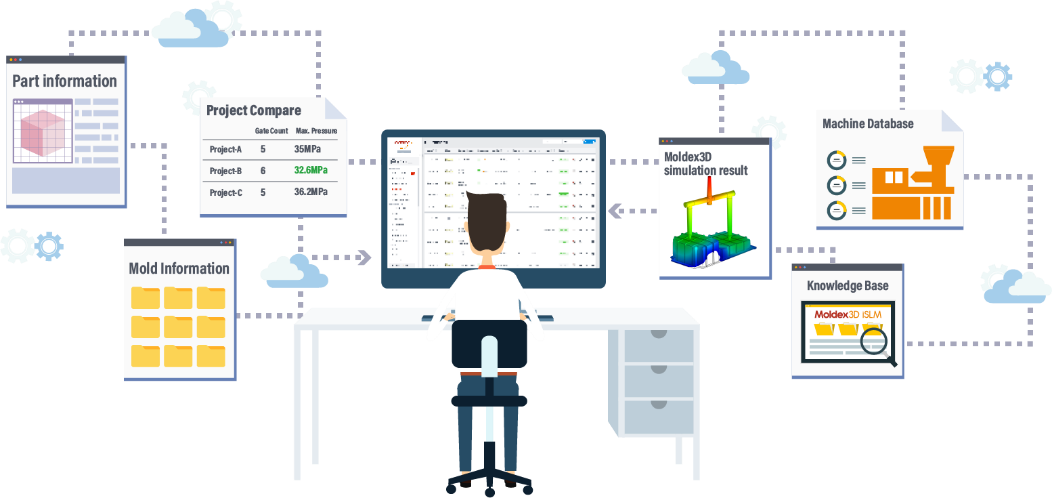

Plastic injection molding is widely used in manufacturing industries around the globe. Traditionally, production-line technicians have relied heavily on their on-site experience to stabilize product quality through mold tryouts and machine adjustments. However, this approach is time-consuming, costly, and prone to inconsistent quality due to discrepancies in decision-making. With the advent of smart manufacturing, these challenges can be addressed by implementing an intelligent management system integrated with AI technologies. Such a system also enhances production efficiency and flexibility.

During the injection molding process, AI helps optimize process parameters through data analytics and real-time prediction. This shortens mold tryout time, enhances production stability, and reduces the risk of human error. In addition, AI enables anomaly detection and predictive analytics, allowing manufacturers to identify potential issues early in the production process and therefore reducing downtime and resource waste.

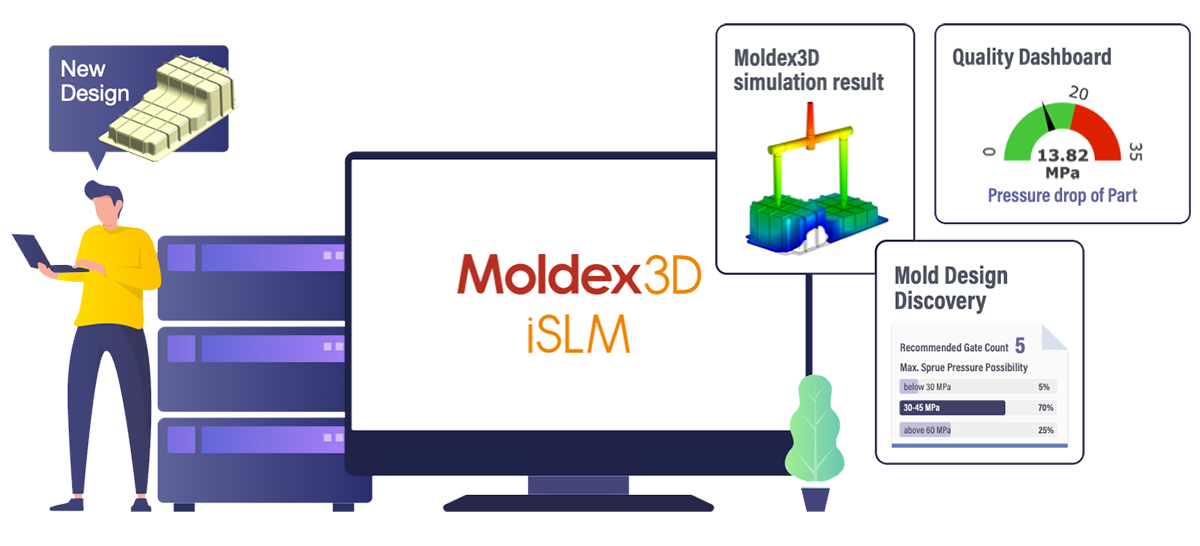

Fig. 1 An intelligent management system integrated with AI enhances production efficiency and flexibility.

iSLM Maximizes the Value of Data

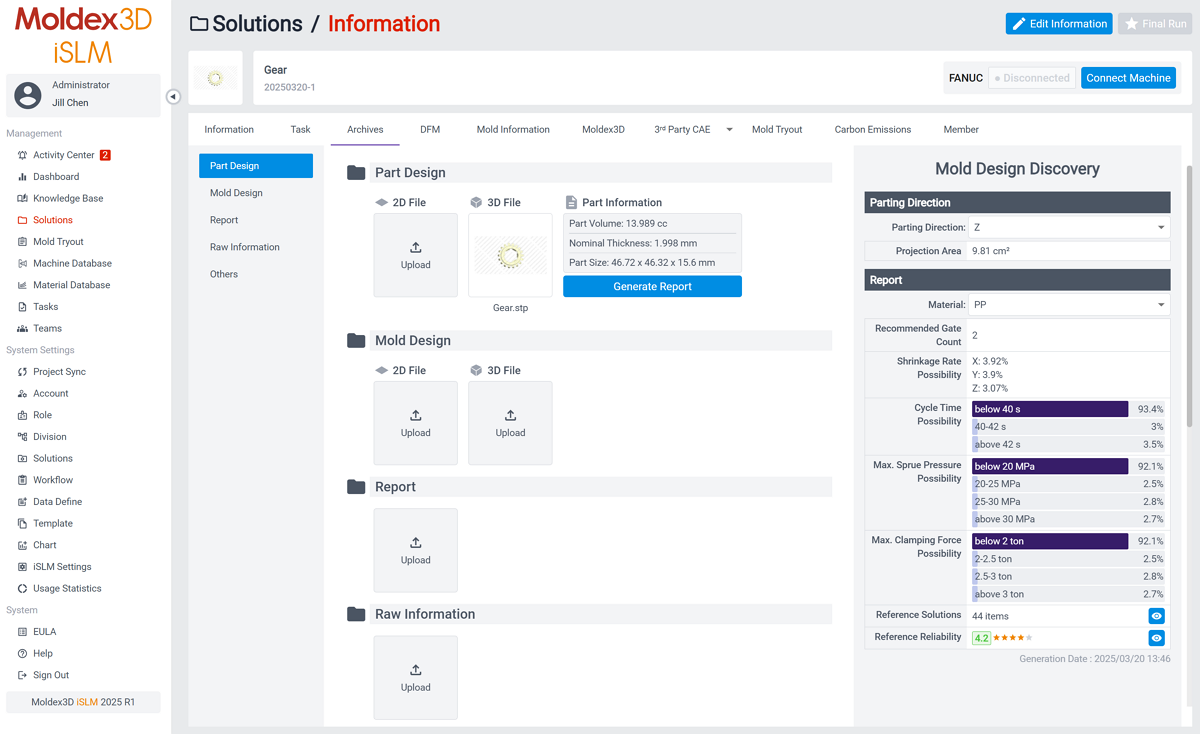

Moldex3D iSLM, a data management platform specifically designed for mold design and plastic molding, helps enterprises build a comprehensive database that records every piece of data and information generated throughout the development process. By integrating automated mold design guidance systems and AI-driven optimization, iSLM extracts maximum value from data, improving overall process efficiency and quality. In 2025, iSLM offers two new functions: Mold Design Discovery and Gate Design Discovery. These functions deliver intelligent molding predictions, helping enterprises quickly identify optimal design solutions.

● Mold Design Discovery

After uploading a new CAD file, the system performs similarity comparisons against historical projects stored in the Knowledge Base. During this process, algorithms analyze the part’s geometry, dimensions, and structure to identify the most relevant reference cases. Once the comparison is complete, the system combines critical information from the database—such as material properties and mold design parameters—to provide predictive insights.

For example, with predicted data on sprue pressure and clamping force, users can determine suitable injection machines in advance. They can also leverage shrinkage predictions to adjust designs accordingly. In addition, predicted cycle times support the evaluation of carbon emissions and cost quotations, enabling smarter business decisions.

Fig. 2 iSLM Mold Design Discovery.

● Gate Design Discovery

In Project Summary, after uploading part model files using the Create Job function, the system performs similarity comparisons against historical projects stored in the Knowledge Base. Once the comparison is completed, the system generates a list of high-similarity gate designs. Users can easily review and reference these cases, then select the most appropriate gate type and location based on requirements and apply them to the new part model. This greatly streamlines and improves the accuracy of the gate-design workflow.

Fig. 3 iSLM Gate Design Discovery.

How iSLM Addresses AI Transparency Concerns

As intelligent technologies are introduced, some users remain concerned about the transparency and explainability of AI features. In regard to automated mold design guidance and AI optimization, users may doubt how AI makes decisions and questions the rationale behind its recommendations, shattering their trust in the system. Moreover, without clear insight into AI model logic and data sources, users may struggle to intervene promptly under abnormal conditions, increasing process risk. To alleviate these concerns, iSLM adopts a careful and explainable approach. It does not directly apply optimized results or designs to the current part model. Instead, iSLM indicates the projects and items referenced to allow users to review the basis and process of every AI-generated decision.

Using Mold Design Discovery as an example, users can view all projects used for similarity comparison and examine reliability indices (aggregated/individual) for reference data. This further assists users in evaluating applicability of the recommended design and allows users to filter or adjust designs based on actual needs, ensuring full flexibility. Likewise, in Gate Design Discovery, the system displays thumbnail images of highly similar gate designs, enabling intuitive comparison of cases. Even after selecting a gate design, users can remove the applied design and revert to manual gate creation to achieve optimal customization.

Fig. 4 iSLM ensures that users can fully review detailed reference information and predicted data.

Conclusion

With the growing demand for diversified and customized products and the rise of smart manufacturing, digital transformation is inevitable. The introduction of AI offers new perspectives and solutions to common molding challenges. To support enterprises in realizing digital transformation, iSLM now integrates AI-driven data analytics and similarity comparison to provide optimal design solutions and predictive results, effectively shortening design and production cycles and improving overall efficiency. In addressing user concerns about AI decisioning, iSLM also presents full lists of referenced projects and items, enabling users to understand the AI decision process and operational mechanisms.