STUDENT CATEGORY

SECOND PRIZE WINNER

Project Name: Fabrication of Microlens Array on Disk Using Micro-Injection Compression Molding Process

School: Taiwan University

By Sen-Yeu Yang, Jiun-Yang Chiou, Ting-Chia Yang

Summary

Summary

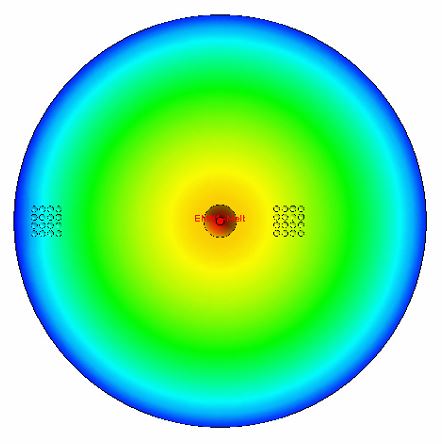

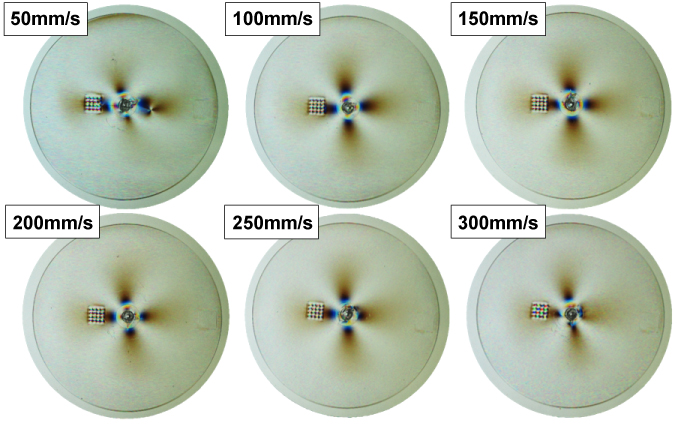

The development of virtual reality displays and wearable devices is rapidly advancing nowadays and the thickness issue caused by the conventional lens with multiple sets of lenses is the first issue that needs to be solved. Therefore, the microlenses with the characteristics of thin, multi-function and array have been developed to solve this issue. Different from the use of sector flow gate for generating the microlens array in the past, this project has developed a rapid and even microlens array molding process with a good optical property. We used Moldex3D molding analysis software to analyze the pros and cons of different runner systems to improve the flaw of loss of cold runner plastic in the conventional runner system and verify the feasibility of disk molding, to optimize the product design with simulation and analysis. Lastly, we compared the influence of injection molding (IM) and injection compression molding (ICM) on the optical property and warpage displacement by adopting the Taguchi’s method to proceed to find the sensitive factors and best parameters, and then the results were verified with the practical molding results.

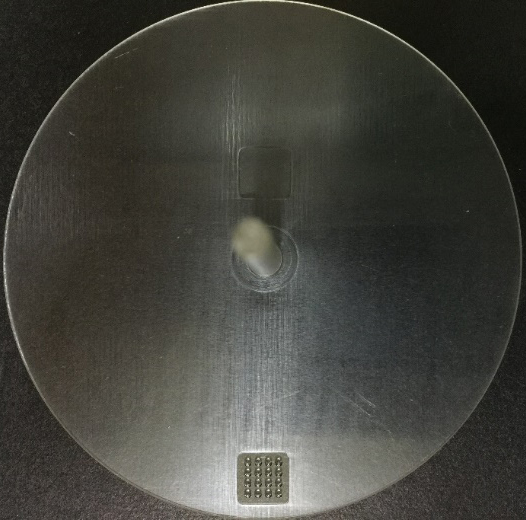

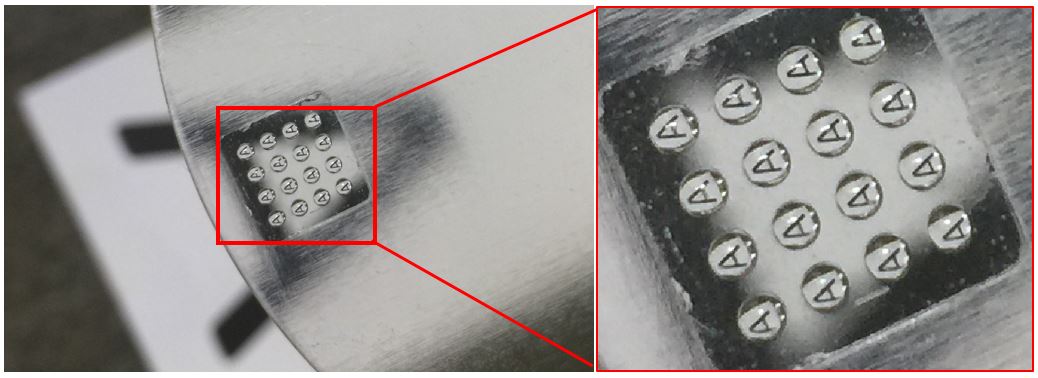

In the practical molding experiment, the double-sided microlens array was successfully produced on a 4-inch disk and we also verified that ICM has a better replication rate, optical property, and residual stress than IM. Moreover, we verified that practical molding has similar results as the simulation. The molding microlens array has the focus function and its imaging is clear. With the assistance of Moldex3D simulation analysis, the molding technology and efficiency of double-sided microlens array have been successfully enhanced to fulfill the requirements of high-performance, small, lightweight, and thin for the current optical industry.

Challenges

Challenges

- The concept of the wafer manufacturing process divides the disk base, improves the runner design, saves materials, and increases the single-mold finished products, to achieve the goal of mass production

- We used Moldex3D to verify the feasibility of the manufacturing process and reduce the time and cost of the repeated trial mold

- Improve the warpage displacement and optical property of product to produce microlens array with low residual stress, high precision, and excellent optical property

Solutions

Solutions

Firstly, we used Moldex3D to analyze the feasibility of mold design to reduce the modification time and cost of the repeated trial mold. Based on the molding state, residual stress, and level of warpage, we find the relevant factors that have a higher impact on warpage and optical property, as well as find the best parameters by adopting the Taguchi methods. We also interpreted the difference between the IM and ICM manufacturing process based on the perspective of in-mold molding and successfully produced a double-sided microlens array on a 4-inch disk. We also verified that practical molding has similar results as the simulation.

Benefits

Benefits

- We conducted the division of multiple sets of microlenses on the disk with a direct flow gate so that the material usage rate is as high as 66.3%, which is about 3 times more than the conventional sector flow gate with only 18.8%

- Based on the molding state, residual stress, and level of warpage, we find the relevant factors that have a higher impact on warpage and optical property, as well as find the best parameters by adopting the Taguchi methods

- The shrinkage rate can be significantly reduced to 1.5-2.0% by using the injection compression molding; it can be reduced to below 1.5% after the optimization with the Taguchi methods

- We used Moldex3D to quickly verify the differences as well as pros and cons between the IM and ICM processes

- Effectively improve the birefringence difference of product and enhance its optical performance

Products Used

Products Used

– ICM

– Flow

– Pack

– Warp

– Optics

Meet the Team

Meet the Team

Our entire overall research process did not always go smoothly. Through continuous trials and experiments, we successfully developed the microlens array on disk. We would like to thank Moldex3D. The Moldex3D software has an excellent process module of injection compression molding and high-quality hybrid mesh, which can help save lots of time in development and has data aligning with the practical condition. In the future, it is expected to develop more new manufacturing process by using Moldex3D, so that the goal of one person to complete the tasks for multiple people can be achieved!