COMPANY CATEGORY

SPECIAL PRIZE WINNER

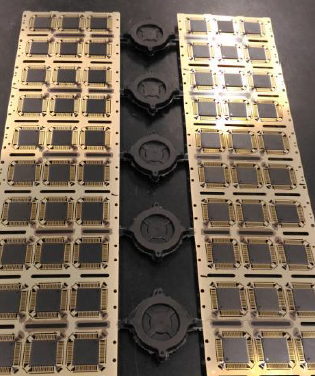

Project Name: Using Moldex3D To Solve Void Issues And Optimize Encapsulation Process

Company: STMicroelectronics

By Marco Rovitto

Summary

Summary

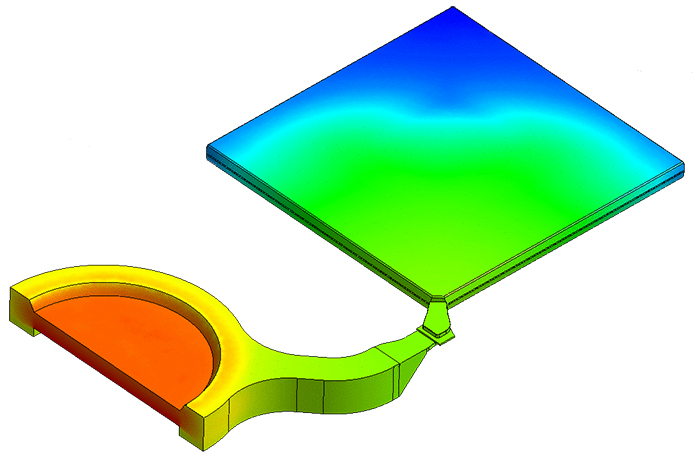

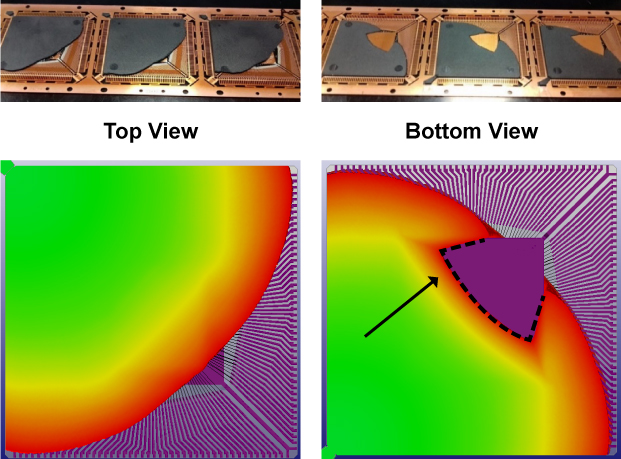

STMicroelectronics engineers minimize the risk of incomplete resin filling by employing Moldex3D IC Packaging solution. First, the software allows to reproduce void formation caused by unbalanced flow behavior. Then, Moldex3D simulation is applied to optimized package design to reduce the risk of issues. As a result, geometric variations show a significant effect on filling front progression avoiding the generation of structural defects during molding process. Virtual failure anticipation with Moldex3D is successful and results are transferred to package prototyping for new product integration.

Challenges

Challenges

- Improving the unbalanced flow behavior

- Reducing the weld lines and voids

Solutions

Solutions

STMicroelectronics designers estimate a reduction of unbalanced resin flow between the top and the bottom of the cavity by decreasing the die pad size of the standard configuration. Since lead frame die pad has been identified as critical location, the optimization of its design shows significant benefits in terms of filling behavior. In fact, this approach reduces the presence of critical weld lines in the product. Therefore, this solution solves voids issues acting first on design rather than experimental prototyping which requires time and money.

Benefits

Benefits

- Finding location with higher probability of critical weld line

- Reduced weld line meeting angle and subsequent probability of void formation

Products Used

Products Used

Meet the Team

Meet the Team