![]() Read the full winning entry

Read the full winning entry ![]() Browse 2013 winners’ gallery

Browse 2013 winners’ gallery

“We have strong confidence in Moldex3D’s simulation results, and we are the first one to use Moldex3D in Turkey. We combine the simulation process with mold manufacturing in order to optimize results. With Moldex3D, it helps us reduce production costs and time greatly and we have been having successful results.”-Evrim Metin, Design Manager, AKSEM

Q: How do you feel about winning the 2013 Moldex3D Global Innovation Talent Award Contest?

Evrim Metin: When we decided to attend this contest, we were quite confident because we are using Moldex3D very often and we have completed many projects. We have strong confidence in Moldex3D’s simulation results. We are the first one to use the software in Turkey. And it was a very good opportunity to use our project to demonstrate our capability.

Q: How did you find out about the contest and what is the driving force behind that made you enter it?

Evrim Metin: We are very confident about our skills. We thought the contest was a good fit to show our capabilities. That’s why we chose to attend this contest.

Q: How did you get the idea of using Moldex3D to optimize manufacturing processes?

Evrim Metin: As I said, we are the first one to use the software in Turkey. We’ve seen a strong demand from our customers to produce better quality products, and that has led us to use Moldex3D. Put it simply, we show the mold simulation results to our customers before creating the actual mold. It helps us save time and money.

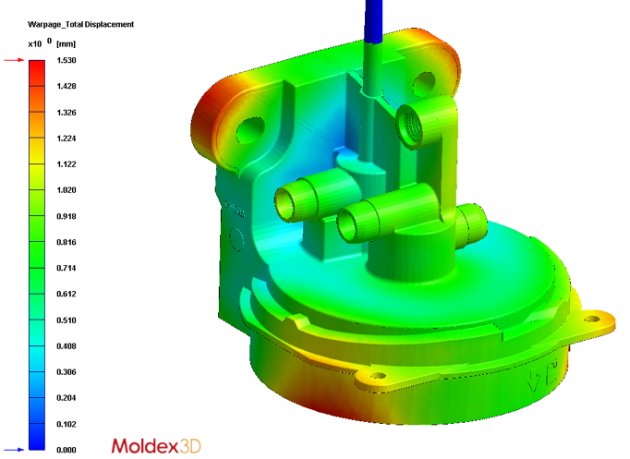

Using Moldex3D to provide warpage prediction to significantly improve the dimensional stability of the part

Using Moldex3D to provide warpage prediction to significantly improve the dimensional stability of the part

Q: What was the greatest challenge during the project? Are there any pain points that you’d like to share with us? And how did you overcome them?

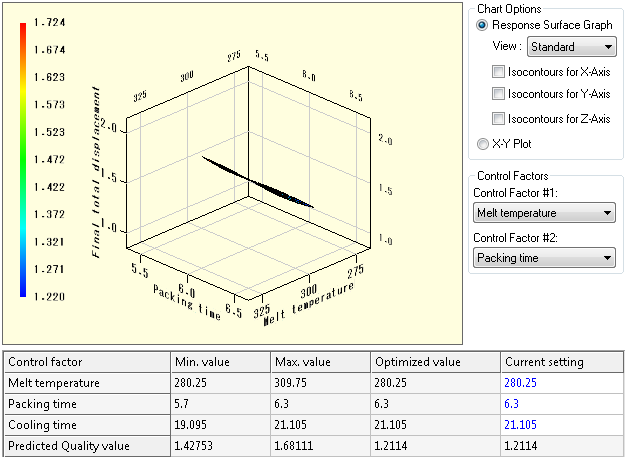

Evrim Metin: There were some critical points that our customers emphasized on. We did not want to use the trial and error method. We wanted to use the CAE approach. Of course, during the developing process in this project, we encountered some difficulties. Moldex3D solution helped us identify problematic areas and addressed them upfront. We were able to resolve our manufacturing difficulties. In addition, we are the first one to use Moldex3D DOE module (Design of Experiment) in Turkey. We focused on creating positive results and I believe we have gained successful results.

The most optimized parameter values were identified by Moldex3D DOE Module

The most optimized parameter values were identified by Moldex3D DOE Module

Q: Any plans for your project going forward?

Evrim Metin: For the future perspective, I can say this project was an example for us and a reference for the company and the sector alike. We combined the simulation process with mold manufacturing in order to optimize results. It largely reduced the production costs. Again with the Moldex3D, the injection molding process has been significantly improved.