STUDENT CATEGORY

SPECIAL PRIZE WINNER

Project Name: Integrating Moldex3D Mold Flow Analysis and Rapid Tooling Technology to Improve the Warpage of Injection Molded Products

School: Ming Chi University of Technology

By Chil-Chyuan Kuo, Yu-Xin Xu

Summary

Summary

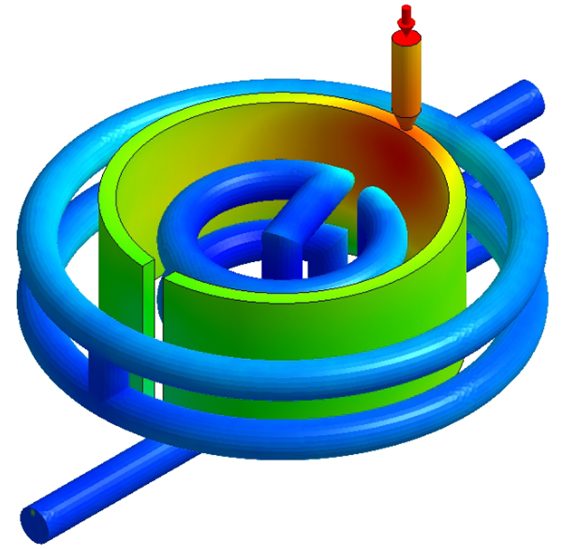

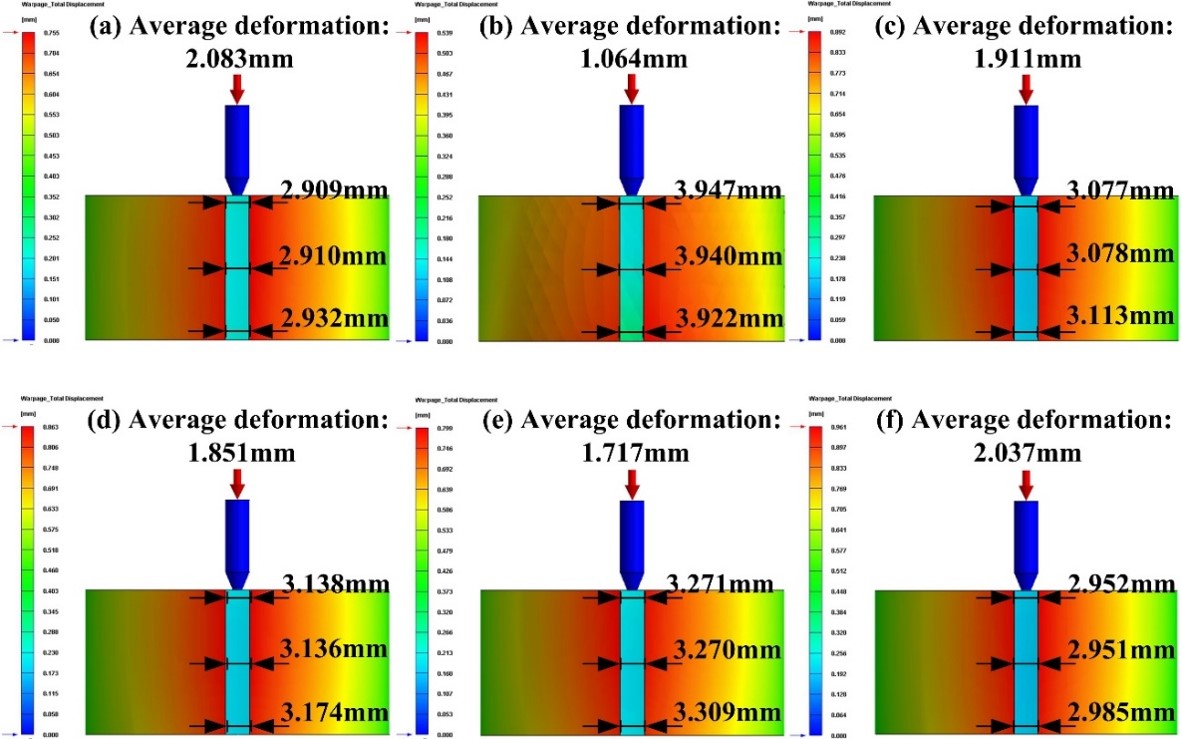

The advantages of rapid tooling mold include high precision, high production efficiency, low production cost, flexible structure, etc. It is suitable for products that require diverse production with a small amount of production, which is the trend in the modern industry. The conformal cooling channel is a unique manufacturing technology utilized in the mold industry. With the development of additive manufacturing methods in the past few years, the conformal cooling channel can adopt the design of the irregular shape of cooling channel, which is close to the appearance of the product to enhance the efficiency of heat dissipation, obtain an even cooling effect, improve the warpage, volume shrinkage, as well as to enhance the productivity and reduce the production cost. This study used Moldex3D molding analysis software to analyze and compare the conventional cooling channel and conformal cooling channel in the rapid tooling mold. We also successfully improved the warpage of the product and enhanced the molding quality of the product.

Challenges

Challenges

- Predict the cooling time of the product

- Predict whether the level of warpage can fulfill the size requirement

- Determine the parameters that have an impact on the level of warpage based on the analysis of cooling and warpage, and improve the research by optimizing the level of warpage

Solutions

Solutions

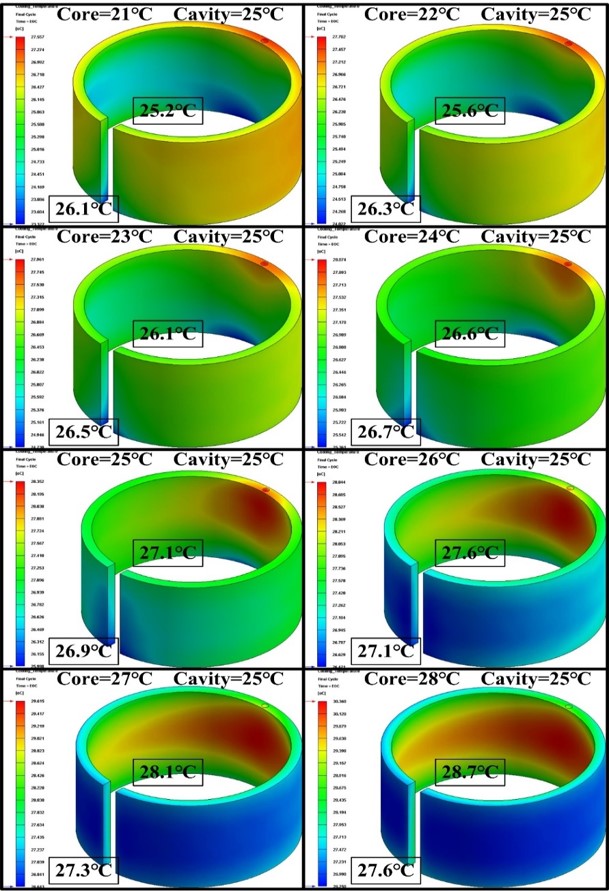

We used the conformal cooling function of Moldex3D to simulate the non-cooling channel, conventional cooling channel, and conformal cooling channel in the rapid tooling mold, and we used different cooling temperatures for the cooling channel in the core and cavity to successfully solve the problem of uneven cooling temperature in the core and cavity, as well as improved the issues such as warpage and error of product size.

Benefits

Benefits

- The cooling effect and temperature influence from different molds and cooling channel designs are clearly demonstrated, and we learned the impact on product warpage as well as the direction for improvement

- Effectively simulate the optimized effect on warpage of product after adjusting the temperature difference of coolant

Products Used

Products Used

Meet the Team

Meet the Team