COMPANY CATEGORY

SPECIAL PRIZE WINNER

Project Name: Application of Moldex3D to Solve the Difficulty of Forming Small Tip Shapes

Company: Eagle Industry Taiwan Corporation

By Tsai-Lung Lin, Chung-Yi Hu, Shih-Ho Wang, Yu-Hsuan Wang, Yan-Jhih Lu

Summary

Summary

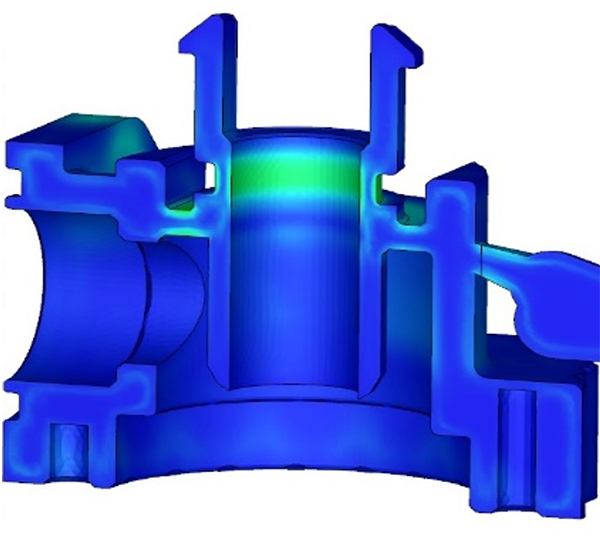

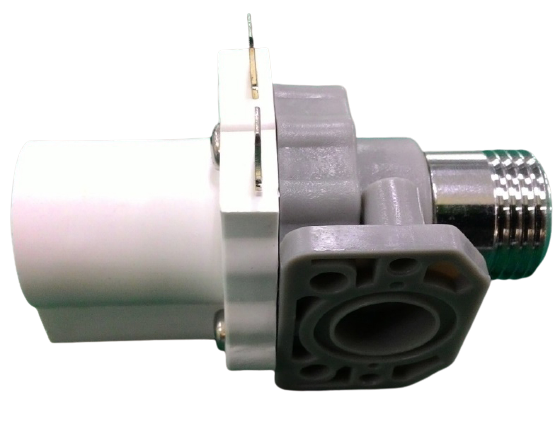

In this case, the product is molded with pom material and it is used as a valve function part in the automatic flushing urinal and automatic faucet. It has thickness restriction and high accuracy requirements in dimension. The room for design change of the finished product and the location can be set for gate are limited. Therefore, under the limited condition of the gate and mold making, we can only optimize the process condition to achieve the high precision molding and solve the thickness issue.

Challenges

Challenges

- Solve the molding issue of the tiny tips of R0.05-R0.02 mm.

- Reduce the size of the void due to its thickness factor without generating flash.

- Obtain a balance of packing section speed, number of seconds, and pressure to solve the issue of void and shrink mark

Solutions

Solutions

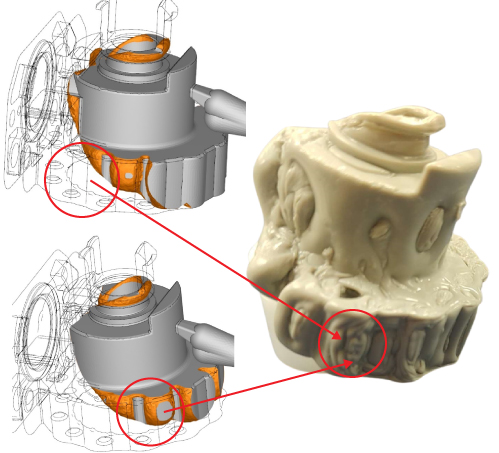

The optimal gate position can be determined by predicting the position of the air trap and weld line based on the mold structure and the characteristics of the finished product.

Find the appropriate VP switching point in accordance with the pressure and temperature data, and find the appropriate number of packing section, number of seconds, speed, and pressure through the data of volume shrinkage rate. Find the location with the smallest shrinkage difference based on the direction and data of the warpage and find the most appropriate imprint location in accordance with the mold mechanism.

Benefits

Benefits

- Determine the best gate location to minimize the weld line and air trap issue in important functional surfaces

- The yield rate of surfaces is enhanced to 97%

- The size of the void is reduced by 30%

- The imprint position is clear without dislocation

- The molding quality exceeds customers’ expectations.

Products Used

Products Used

- Moldex3D Professional Package

– Flow

– Pack

– Cool

– Warp

– Designer BLM

Meet the Team

Meet the Team

It was an honor to represent the company to join the molding analysis contest for the first time and won the special prize in the enterprise group, which is a great recognition and honor for two-year users.We would like to thank Manager Lin for valuing the importance of molding analysis as well as the cooperation among team members. We combined practical and theoretical analysis to complete this project which had practically solved the issues encountered in mass production and obtained a fine product exceeding expectations.In the future, we will continue to enhance our analytical capability and make the virtual analysis more consistent with the practical condition to solve more problems, as well as improve the prediction accuracy of problems and achieve better results.

In addition, we would also like to thank the CoreTech in Tainan for immediate responses and solutions regarding molding issues.