COMPANY CATEGORY

SPECIAL PRIZE WINNER

Project Name: Electric Tool – Optimize the Handle of a Compound Beveling Machine

Company: Good View Industrial Company Limited, Dongguan

By Jian Yang, Weihang Luo, Jun Huang, Yuefei Liu

Summary

Summary

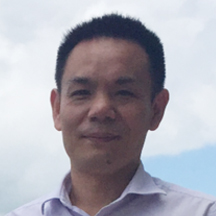

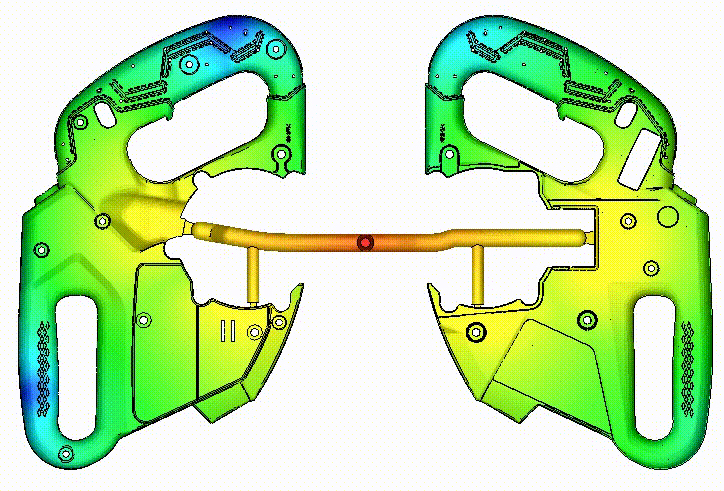

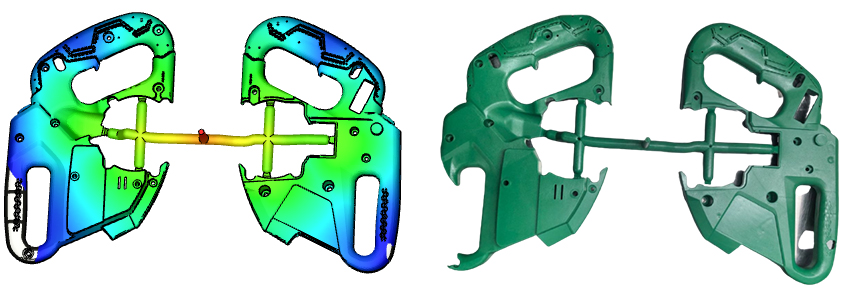

The product is the handle of a compound beveling machine of an electric tool. It uses PC+15GF plastic and it is molded with a cold runner. It has been produced for two years.The produced mold is three-point gating and three people are required for the process as the used material becomes very hard after molding; at present, the production and optimization department of Good View expects to reduce the production cost of the product without having much impact on the quality of the product by optimizing the runner design and adjusting the process conditions. We use the Moldex3D molding analysis to verify the feasibility.With the analysis of molding conditions on the site, we verify the accuracy of the analysis result of the current runner design and reduce the runner size or single-point gating. With the adjusted the process conditions, the deformation and pressure for the design of plastic reduction can fulfill customers’ requirements.

At last, the cost of labor and raw materials can be reduced and the number of molding trials can also be reduced.

Challenges

Challenges

- The pressure loss of the gating is relatively large after the runner plastic reduction, and the pressure loss is expected to be reduced by adjusting the process condition

- The warpage of product needs to fulfill customers’ requirements after the runner plastic reduction

- Reduce the molding cycle of the product

Solutions

Solutions

We used Moldex3D BLM for analysis and verified the correctness of the analysis results of the original design. After the runner plastic reduction, we analyzed and compared the difference with the original design and adjusted the process conditions to reduce its deformation and pressure as well as shorten the production cycle.

Benefits

Benefits

- Reduce the labor costs by 67%

- Save materials and reduce the cost of raw materials by 33%

- Properly adjust the molding parameters through molding analysis and verification to reduce the number of molding trials

- Accumulate experience for the same type of products

Products Used

Products Used

- Moldex3D Professional Package

– Flow

– Pack

– Cool

– Warp

– Fiber

– Moldex3D Studio

Meet the Team

Meet the Team