COMPANY CATEGORY

SPECIAL PRIZE WINNER

Project Name: Apply Moldex3D to Improve the Family Molding Problem of Laptop Keyboard to Increase Productivity and Yield Rate

Company: Lite-On Technology Corporation

By Alan Ting, Jason Wu

Summary

Summary

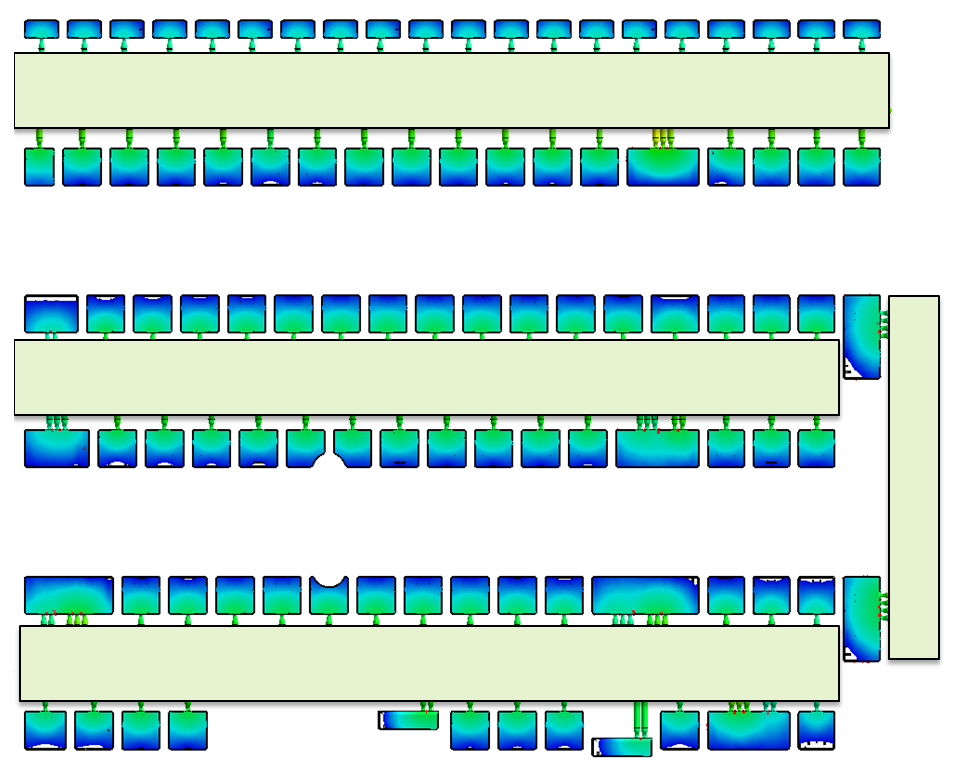

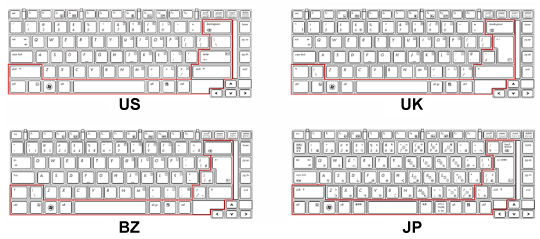

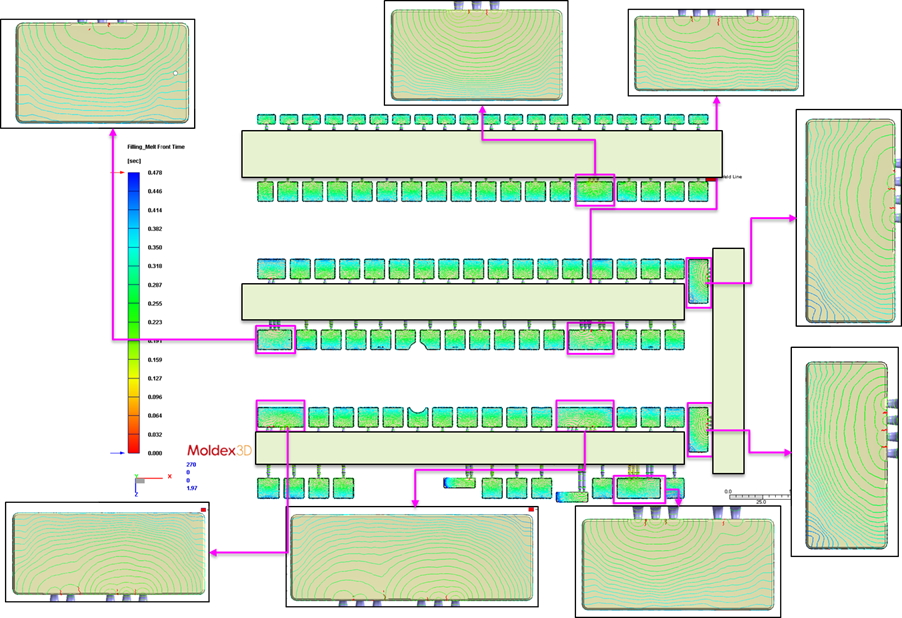

The traditional laptop keyboard needs to adopt multiple sets of loose KEY molds for molding of word keys with different sizes. If the product of different sizes is developed at the same time, the excessive number of individual mold sets will result in subsequent costs in frequent mold changes, labor, and time. However, it usually causes issues such as flash and poor size if the fish-bone arrangement of family mold is adopted for molding. We mainly used Moldex3D to conduct adjustment and analysis for the runners in advance and integrated dozens of sets of word key molds into the same set of mold to control the flow balance to fulfill the requirements of improving the size and appearance at the same time.

Challenges

Challenges

- Flow balance of one mold with multiple cavities

- Improve the appearance issue such as flash, stress mark, and weld line

- The same set of family mold needs to mold four materials

- Reduce the number of mold sets

Solutions

Solutions

Apply Moldex3D to simulate the condition of the generation of shearing heat in runners to optimize the runner design. Adjust the configuration of a cold runner and hot runner to solve issues such as flow imbalance, flash, stress mark, weld line, and warpage that are easily caused in one mold with multiple cavities.

The optimized family mold can effectively reduce the number of mold sets and integrate four types of materials to overcome the difference in viscosity of materials. Integrate dozens of mold sets into one set of mold for injection molding to reduce labor costs such as mold assembly and replacement.

Benefits

Benefits

- Family mold effectively improves the flow balance to above 90%

- Control the length of the weld line and solve the issues such as cold material mark and stress mark

- One set of family mold can mold four different materials so that the number of mold sets can be reduced

- Improve the yield rate

- Reduce manpower

Products Used

Products Used

- Moldex3D Advanced Package

– Flow

– Pack

– Cool

– Warp

– 3D Coolant CFD

– Designer BLM

– Moldex3D Mesh

– Studio

– CADDoctor

– Stress

Meet the Team

Meet the Team